Woodworking Machine Bearings

-- Steady & Reliable Manufacturer --

Brief Description

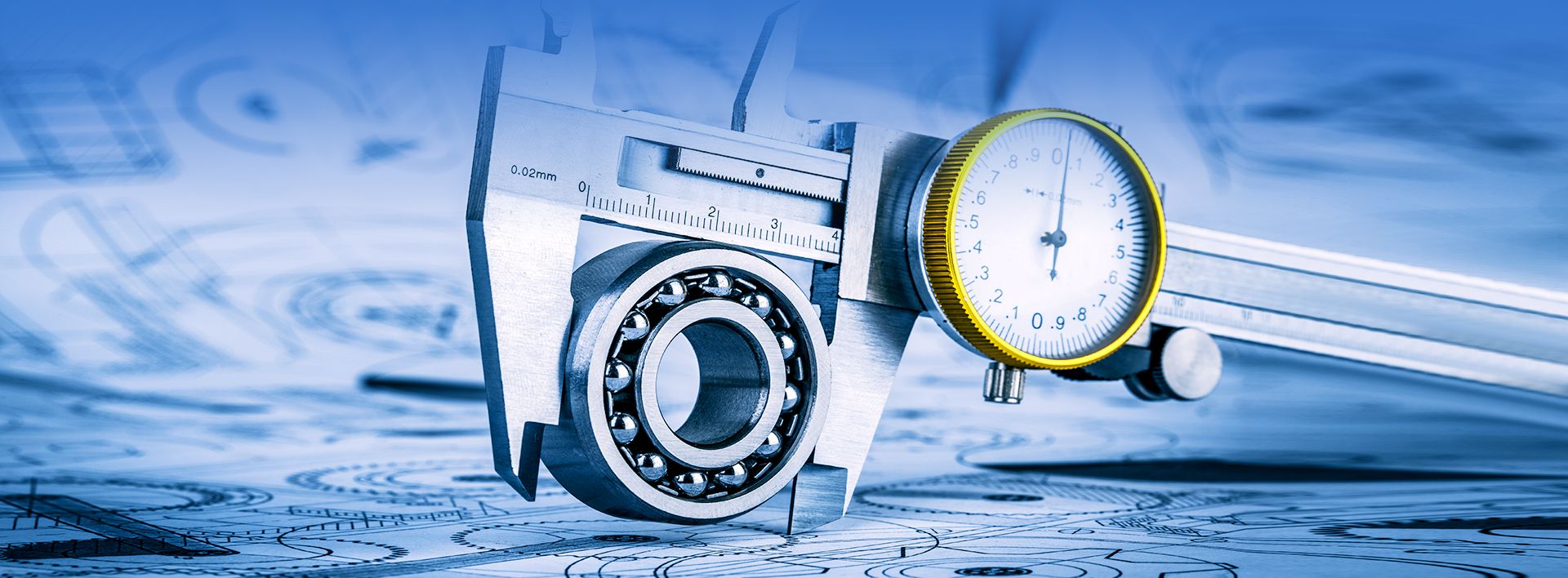

High-speed, precision ball bearings with enhanced sealing to withstand the continuous presence of fine abrasive wood dust, ensuring accurate cuts and smooth spindle operation.

Introduction

Woodworking machinery, from CNC routers to industrial planers, generates massive amounts of fine, highly abrasive dust, which is extremely detrimental to bearing life. Our bearings for this sector, commonly high-speed deep groove or Angular Contact Ball Bearings (ACBB), feature specialized contact seals (2RS/LLB) designed specifically to exclude fine particles. Furthermore, the bearings are designed for high-speed capability and high running precision (P5) to maintain the cutting accuracy required for quality finished goods, all while operating reliably despite the harsh environment.

Related products

Specification Standards

| Key Feature | Precision Grade | NSB Offering |

|---|---|---|

| Contamination Focus | Wood Dust / Fine Particles | Requires robust, low-friction contact seals. |

| Precision Class | P5 (ABEC 5) | Standard for high-speed router and saw spindles. |

| Sealing System | Low-Friction Contact Seals (2RS/LLB) | Offers the best defense against abrasive contaminants. |

| Design Type | ACBBs (Paired) or DGBB | ACBBs are preferred for high axial load spindles (routers). |

| Cage Material | Polyamide or Steel | Optimized for high-speed operation and durability. |

Applications

-

CNC Router Spindles: Ultra-high speed, high-precision operation.

-

Saw Arbors: Circular saws, panel saws, and band saw wheels.

-

Planers & Moulders: High-speed cutter head support.

-

Edge Banders: Support rollers and drive mechanisms.

Key Advantages

-

Maximum Dust Exclusion: Specific 2RS/LLB seal designs are highly effective at blocking the ingress of fine wood particles.

-

High Accuracy: P5 precision maintains the tight tolerances needed for clean, accurate cuts, minimizing waste.

-

Thermal Resilience: Designed to run cool at high RPMs, extending the life of critical spindle components.

-

Shock Load Tolerance: Robust construction handles the sudden impact and vibration from cutting materials.

Ningbo Sanya Bearing Co., Ltd. is a professional China Woodworking Machine Bearings Manufacturers and Custom Woodworking Machine Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.