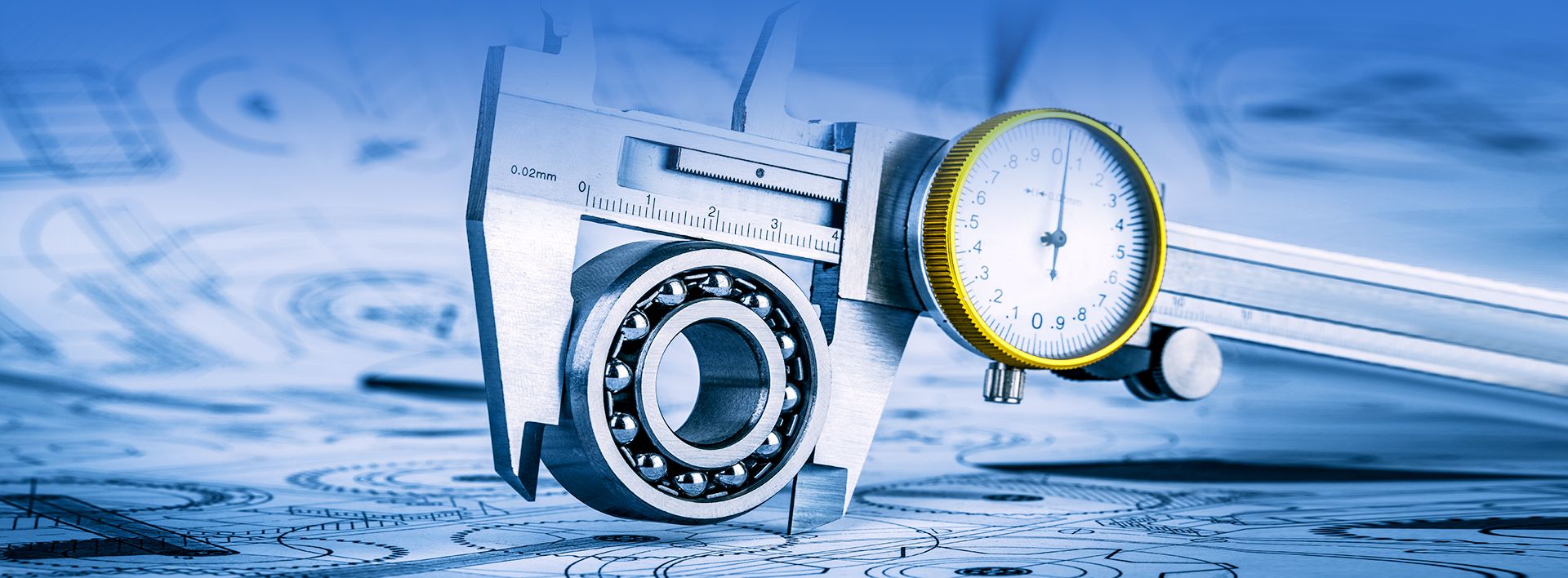

Ningbo Sanya Bearing Co., Ltd. is professional

China Plain Bearings Manufacturers, established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the high-quality deep groove ball bearings and insert bearings. It has emerged as a modern

OEM Plain Bearings Suppliers, integrating product development, design, manufacturing, sales and service. It can produce and

Wholesale Plain Bearings with an inner diameter of 3mm to 100mm and customize various non-standard products with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products.

With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.