Textile Machinery Bearings

-- Steady & Reliable Manufacturer --

Brief Description

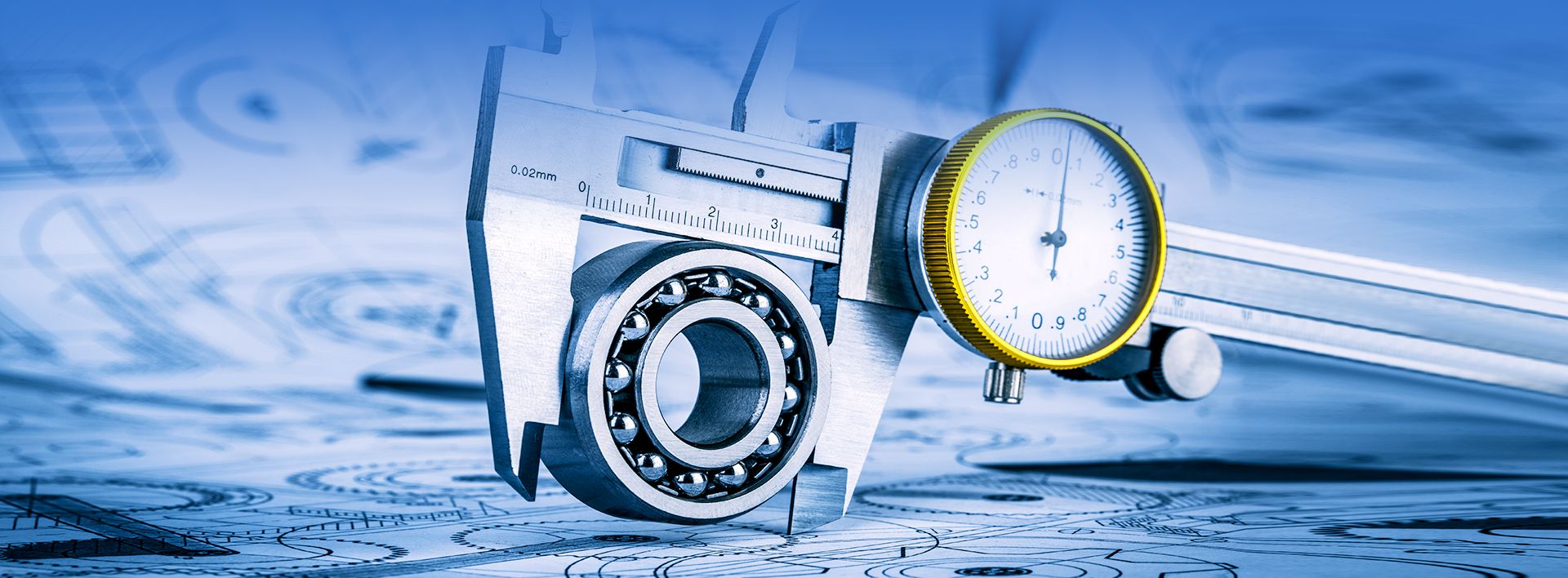

High-precision, high-speed bearings engineered to minimize friction and withstand the unique challenges of fine dust and fiber contamination in modern textile processing equipment.

Introduction

The textile industry demands bearings that can maintain extremely high and consistent rotational speeds (especially in spinning spindles) with near-zero vibration, which is critical for product quality and yarn consistency. The environment, however, is harsh, filled with fine fiber dust, which poses a severe risk of contamination. Our specialized bearings feature highly effective sealing mechanisms and often use P5 or P4 (ABEC 5/7) precision ratings. We pay particular attention to cage materials, sometimes utilizing special plastics (e.g., phenolic resin) that can handle high speeds and are less susceptible to friction heat.

Related products

Specification Standards

| Key Feature | Standard Requirement | NSB Offering |

|---|---|---|

| Precision Class | P5 (ABEC 5) and P4 (ABEC 7) | Essential for high-speed spindles and rollers. |

| Speed Capability | Very High (up to 40,000 RPM) | Utilizing specialized cage design (often high-speed Polyamide). |

| Internal Clearance | C3 or C4 | To manage the temperature rise common in high-speed spinning. |

| Contamination Resistance | High | Specialized seals and shields to block lint and dust. |

| Lubrication | Low-noise, heat-resistant spindle oil/grease | Optimized to reduce operating temperature and noise. |

Applications

-

Spindles: Ring spinning, open-end spinning, and texturizing machines.

-

Looms and Weaving Equipment: Rollers and guides requiring consistent alignment.

-

Processing Rolls: Calendering, printing, and drying machinery.

-

Blowroom & Carding: Large, slower-moving components that require robustness against heavy fiber contamination.

Key Advantages

-

Vibration Minimization: Ultra-precise manufacturing limits vibration, which directly improves the quality and tensile strength of the processed yarn.

-

Fiber Dust Blocking: Engineered seals are designed specifically to resist the fine, pervasive fiber dust that causes abrasive wear and seizure in standard bearings.

-

Thermal Reliability: High-speed compatibility and optimized internal design prevent premature failure due to excessive heat generation.

-

Long Maintenance Cycles: Specialized lubrication allows for extended operational time between necessary service interventions.

Ningbo Sanya Bearing Co., Ltd. is a professional China Textile Machinery Bearings Manufacturers and Custom Textile Machinery Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.