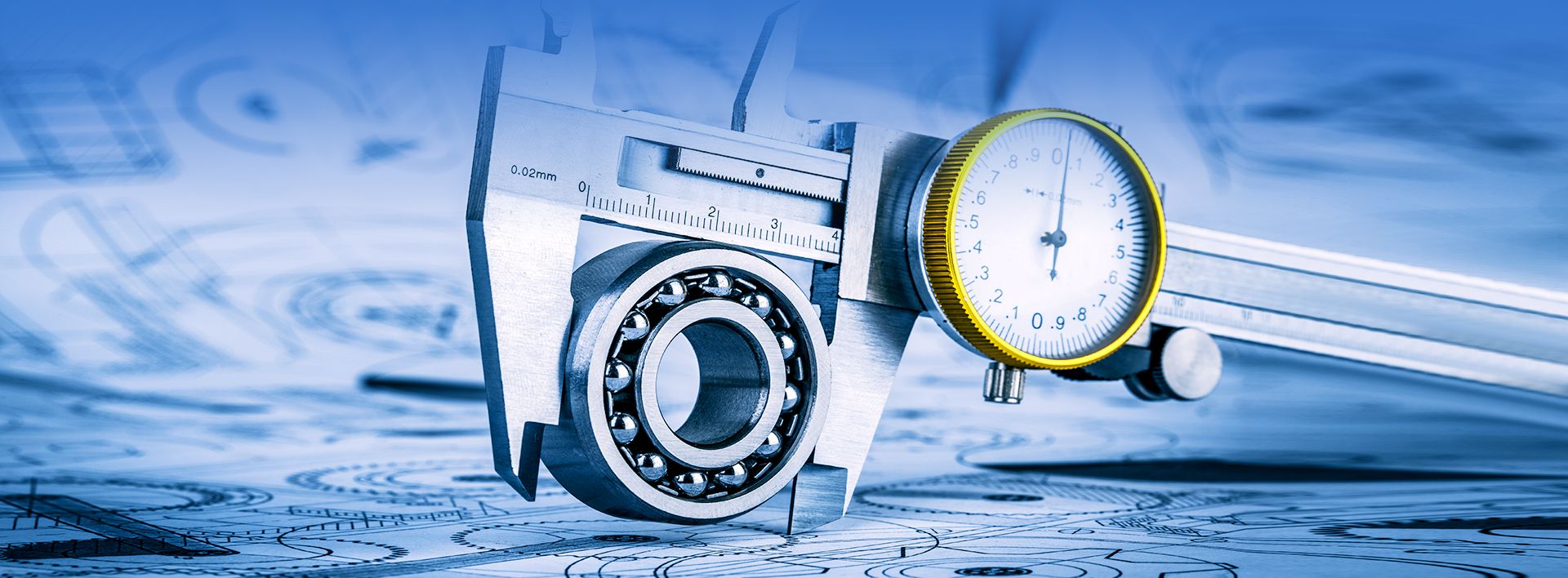

Electric Motor Bearings

-- Steady & Reliable Manufacturer --

Brief Description

High-reliability, low-vibration bearings are designed for the demanding operating cycles of AC and DC motors, ensuring maximum motor efficiency and minimizing noise during operation. As a crucial component within the motor, the performance of motor bearings directly impacts the overall operating condition and lifespan of the motor. Therefore, the design of these bearings must consider multiple requirements, including load capacity, durability, vibration control, noise suppression, and efficient thermal management.

1. High Reliability: These bearings utilize advanced materials and precision manufacturing processes, enabling stable operation under high loads and high speeds, ensuring the motor remains fault-free during long-term operation. Bearing reliability depends not only on material selection but also on surface treatment, lubrication methods, and precise assembly processes. The use of special wear-resistant materials and low-friction coatings allows the bearings to maintain good performance even in harsh environments, extending service life and reducing maintenance frequency and costs.

2. Low Vibration Design: Vibration during motor operation not only affects the stability of the motor itself but can also be transmitted to other mechanical components, potentially causing equipment failure. To minimize vibration, these bearings reduce dynamic imbalance and frictional torque during operation through optimized design, precision manufacturing, and rigorous quality control. Especially at high speeds, low-vibration bearings effectively reduce vibration caused by imbalance or assembly errors, ensuring smooth and precise motor operation.

3. Maximizing Efficiency: High-efficiency bearings reduce mechanical losses and energy waste, improving the overall efficiency of the motor. By using low-friction materials and optimized lubrication schemes, these bearings operate with lower energy loss, helping the motor maintain efficient operation under various load conditions. This not only reduces motor energy consumption but also alleviates overall system heat generation, improving operational stability and environmental friendliness.

4. Noise Suppression: Noise is a crucial consideration in motor applications, especially in applications requiring low-noise environments (such as home appliances, office equipment, and medical equipment). To effectively suppress noise, these bearings are designed with vibration damping and noise reduction in mind. By optimizing the geometry of the inner and outer rings, adjusting the arrangement of rolling elements, and using specialized noise-suppressing materials, sound output during operation can be significantly reduced, achieving quiet or low-noise operation and enhancing the user experience. 5. High Temperature Resistance and Thermal Management

During long-term high-load operation of electric motors, the increased temperature experienced by bearings can lead to lubricant failure, material fatigue, or deformation, thus affecting their performance. Therefore, these bearings utilize high-temperature resistant materials, and their optimized structural design effectively dissipates heat, ensuring good operating performance even in high-temperature environments. Through proper thermal management, the bearings can operate stably and continuously under extreme temperatures, reducing performance degradation caused by temperature fluctuations.

Introduction

Electric motor bearings are often referred to as the silent workhorses of the electrical machinery world. These seemingly simple components play a critical role in the efficient operation of electric motors by supporting the rotor and enabling smooth, continuous rotation. Despite their small size, bearings are subjected to immense pressures due to the high-speed rotation of the motor, especially in demanding industrial applications where motors run for hours, days, or even years without interruption.

The Challenges Facing Electric Motor Bearings

In the world of electric motors, bearings face a range of challenges that affect their longevity, performance, and overall reliability:

High-Speed Rotation: Electric motors typically operate at high speeds, with some motors reaching speeds upwards of 10,000 RPM (revolutions per minute). These rapid rotations generate significant centrifugal forces that place high demands on the bearings’ structural integrity and stability.

Heat Generation: Continuous operation at high speeds generates friction within the bearing components, leading to increased temperatures. If not properly managed, excessive heat can degrade the bearing materials, accelerate wear, and reduce the lifespan of the bearing, which ultimately shortens the lifespan of the entire motor.

Vibration and Impact: Motors often operate under fluctuating loads and varying conditions, which can cause vibration, shock loading, or sudden impacts. These forces can cause premature bearing failure if the bearings are not designed to withstand such stresses.

Precision and Accuracy: Bearings in electric motors need to be manufactured to extremely tight tolerances. Any deviation from the optimal running clearance or misalignment can lead to increased friction, noise, and uneven wear, which ultimately reduces the motor's efficiency.

Environmental Conditions: Many electric motors are used in harsh environments, such as in high-temperature, humid, or corrosive atmospheres. Bearings in these conditions must be designed to resist corrosion, wear, and degradation from exposure to these elements.

Superior Bearing Design for Maximum Durability

To overcome these challenges, the design of electric motor bearings is critical. Our motor bearings are engineered with advanced materials and cutting-edge technologies to provide exceptional performance even under the most demanding conditions.

Optimized Heat Treatment: Heat treatment is a vital process in bearing manufacturing, as it enhances the hardness and wear resistance of the bearing steel. Our bearings undergo specialized heat treatment processes that improve their resistance to thermal cycling, helping them maintain their strength and performance even in high-temperature environments. This contributes to the extended life and reliability of the bearings, reducing the frequency of maintenance and replacement.

Advanced Cage Designs: The cage, or retainer, in a bearing plays a vital role in maintaining the correct spacing between the rolling elements. Our bearings are designed with specialized cage structures that minimize friction and heat generation while maximizing the efficiency of the bearing’s operation. Additionally, the design of our cages helps reduce vibration levels, further improving motor performance and extending the bearing’s lifespan.

Improved Running Accuracy and Internal Clearance: The internal clearance of a bearing—how tightly or loosely the rolling elements are fitted inside the raceway—has a direct impact on performance. Bearings with excessive clearance may lead to greater friction and noise, while insufficient clearance may cause overheating and premature wear. Our bearings are manufactured with ultra-tight tolerances to ensure optimal running accuracy and minimize unnecessary friction. This precision ensures that the bearing operates smoothly even at high speeds, reducing the risk of wear and ensuring a longer service life for the motor.

Low Vibration Levels: Vibration is a leading cause of bearing damage in electric motors. To mitigate this, we carefully design bearings to minimize vibrations during operation. This is achieved by employing advanced manufacturing techniques that ensure the bearing’s components are properly aligned and balanced. Our bearing solutions also incorporate materials and designs that absorb or dampen vibration, helping to reduce noise and enhance motor efficiency.

Corrosion Resistance: Bearings used in electric motors must be resistant to corrosive environments, whether due to moisture, chemicals, or salt exposure. We offer bearings made from high-quality stainless steel or specialized coatings that provide excellent protection against corrosion. This ensures that our bearings continue to perform optimally even in challenging or extreme environmental conditions.

Related products

Specification Standards

| Key Feature | Standard Requirement | NSB Offering |

|---|---|---|

| Precision Class | P6 (ABEC 3) or P5 (ABEC 5) | Typically P5 for optimal performance. |

| Noise & Vibration | Z2, Z3, or Z4 (V1, V2, V3) | V2 or V3 grade for low-noise operation. |

| Internal Clearance | C3 or C4 | Tightly controlled C3 for temperature compensation. |

| Cage Material | Stamped Steel (Standard) or Polyamide (High Speed) | Optimized for speed and operating temperature. |

| Lubrication | Polyurea Grease (High Temp/Long Life) | Sealed and pre-lubricated for life. |

Applications

-

Industrial Drives: Fans, pumps, compressors, and blowers.

-

Consumer Electronics: Washing machines, vacuum cleaners, and power tools.

-

Automotive Systems: Alternators, starters, and electric vehicle (EV) traction motors.

-

Power Generation: Small to medium-sized generators and servo motors.

Key Advantages

-

Ultra-Low Noise Profile: Through advanced super-finishing technology, ensuring V3 vibration levels and reducing audible noise.

-

Extended Service Life: Optimized internal geometry and specialized high-performance grease provide long service intervals.

-

High Thermal Stability: Engineered to perform reliably under the heat generated by high-speed electrical currents.

-

Corrosion Protection: Available with specific coatings for use in humid or wet operational environments.

Ningbo Sanya Bearing Co., Ltd. is a professional China Electric Motor Bearings Manufacturers and Custom Electric Motor Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.