Electric Motor Sealed Bearings

-- Steady & Reliable Manufacturer --

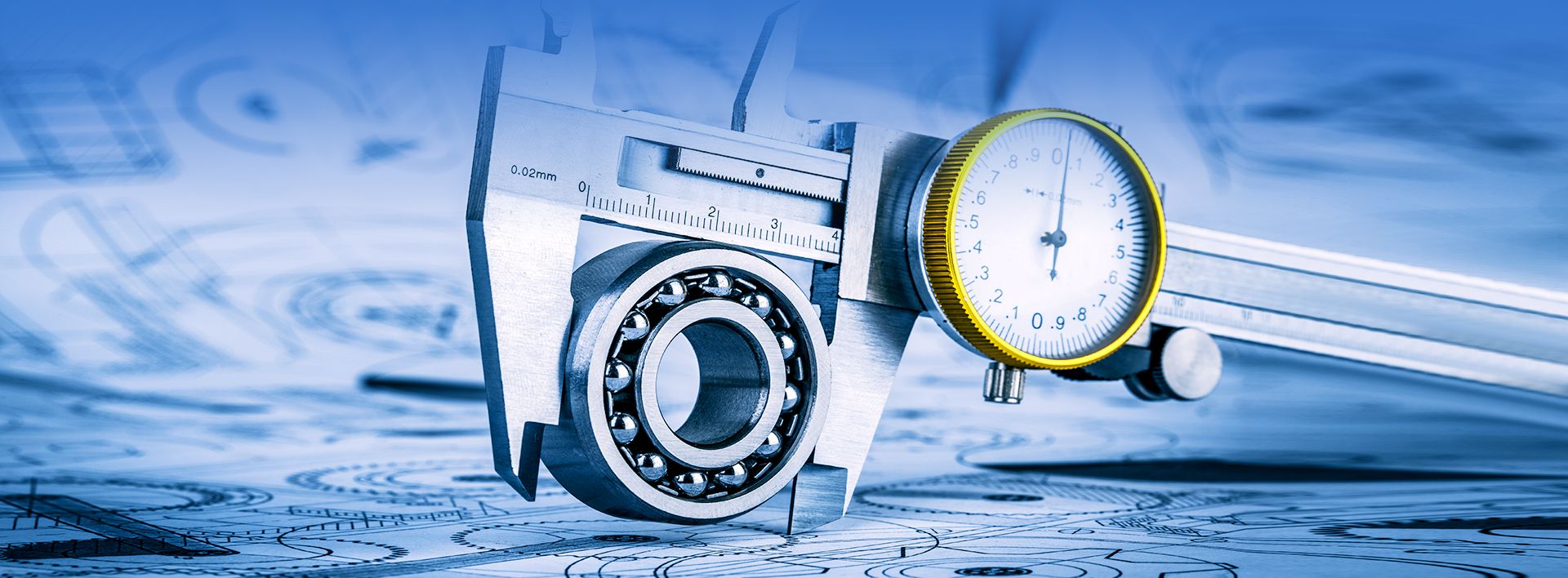

Introduction to Optimized Sealed Bearings for Electric Motors

The modern electric motor demands a bearing solution that delivers unwavering reliability, maximum energy efficiency, and total contamination exclusion. Our Electric Motor Sealed Bearings, primarily Deep Groove Ball Bearings (DGBB), are engineered with optimized internal geometries and specialized lifelong grease fills. The integral seals (2RS) or shields (ZZ) are not just dust covers; they are precision components designed to maintain the integrity of the critical lubrication, protecting against dust, moisture, and even aggressive cleaning agents, thereby extending the motor's operational lifespan and eliminating the need for routine relubrication.

Related products

Technical Parameters for Motor Reliability

| Feature | Technical Requirement | NSB Advantage/Design |

|---|---|---|

| Bearing Type | Deep Groove Ball Bearings (DGBB) | Commonly 6200, 6300 series, preferred for high-speed, low-friction operation. |

| Precision Grade | P6 (ABEC-3) and P5 (ABEC-5) | High precision grades ensure minimal runout, lower vibration, and reduced energy losses. |

| Sealing Type | Integrated Rubber Seals (2RS) or Shields (ZZ) | Low-friction Light-Contact Seals are used to provide the best balance between exclusion of contaminants and minimizing running torque. |

| Grease Specification | Polyurea or High-Performance Lithium Complex | High-stability grease with a wide temperature range, optimized fill volume (typically 25%-35%) for quiet, lifelong operation. |

| Insulation Option | Optional Ceramic Coated Outer Ring | Available upon request to provide electrical insulation for motors driven by Variable Frequency Drives (VFDs), preventing current damage. |

Key Applications in Electrical Machinery

-

Industrial Motors: AC/DC motors, servo motors, and gearmotors used in automated manufacturing and robotics.

-

Pumps and Fans: Motor assemblies for industrial ventilation, water pumps, and high-efficiency air compressors.

-

Power Generation: Smaller generators and backup power units where long-term, maintenance-free operation is valued.

-

Home Appliances: High-reliability motors for washing machines, power tools, and vacuum cleaners.

Critical Performance Benefits for OEMs

- Maintenance-Free Reliability:

Sealed and lubricated for life, drastically reducing the total cost of ownership (TCO) by eliminating the need for periodic relubrication.

- Energy Efficiency and Low Torque:

Precision geometry, light-contact seals, and optimized grease fill minimize frictional drag, directly contributing to motor energy savings.

- Protection Against Electrical Damage:

Optional insulated designs protect bearing surfaces from fluting damage caused by electrical currents common in modern inverter-controlled systems.

- Quiet, Stable Operation:

P5/P6 precision grades ensure smooth running, critical for noise-sensitive applications and preventing vibration-related issues.

Ningbo Sanya Bearing Co., Ltd. is a professional China Electric Motor Sealed Bearings Manufacturers and Custom Electric Motor Sealed Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.