Automotive Wheel Bearings

-- Steady & Reliable Manufacturer --

Brief Description

High-Performance Integrated Wheel Hub Bearing Units are core precision components within modern automotive suspension systems, designed to meet increasingly stringent vehicle performance and safety standards. These units serve as the critical link between the drive system and the wheel, playing a decisive role in a vehicle’s handling, fuel efficiency, driving comfort, and, most importantly, road safety.

Key Features and Design Advantages

-

Exceptional Load Handling Capability:

- Specifically engineered to withstand extreme radial (perpendicular to the axle) and axial (parallel to the axle) loads.

- Maintains excellent rigidity and stability during high-speed driving, sharp turns, heavy loads, or when traversing rough terrain.

- High dynamic load capacity ensures continued reliable performance even under severe operating conditions.

-

Highly Integrated Structure:

- Unlike traditional bearing components that require separate assembly, integrated units typically combine the bearing, flange, seals, and sometimes the wheel speed sensor (e.g., ABS/ESP sensor) into a pre-assembled, maintenance-free whole.

- This design significantly simplifies the assembly process for vehicle manufacturers and ensures tighter installation tolerances.

-

Enhanced Vehicle Performance and Safety:

- The bearing unit is optimized to achieve minimal friction torque, which helps reduce fuel consumption and improves power transmission efficiency.

- Its high precision and rigidity are crucial for maintaining accurate wheel alignment angles, thus ensuring the vehicle’s steering precision and stability.

- Superior sealing technology effectively prevents the ingress of water, dust, and road contaminants, preserving the cleanliness of the internal grease, thereby significantly extending the bearing’s service life and long-term performance.

Core Value

High-Performance Integrated Wheel Hub Bearing Units are a critical guarantee of vehicle safety. They not only provide smooth and quiet operation but also ensure reliable wheel rotation under all driving conditions, serving as an indispensable technical foundation for achieving long-lasting reliability and an excellent driving experience.

Introduction

Automotive wheel hub bearings are safety-critical core components of the suspension system. They not only bear the entire weight and driving forces of the vehicle but must also continuously endure the severe stresses of the road environment. Our wheel bearing product line is specifically engineered to provide unparalleled reliability and extended durability under these high-load, high-contamination conditions.

Uncompromising Performance in Harsh Environments

Wheel bearings operate in extremely demanding conditions, constantly defending against:

- Road Contaminants: Abrasive particles like dust, mud, and grit.

- Moisture Ingress: Wet environments caused by rain, snowmelt, and high-pressure washing.

- Significant Shock Loads: Instantaneous, high-intensity impacts resulting from potholes, bumps, or accidental collisions.

Our products are meticulously designed and validated to ensure the cleanliness and lubrication integrity within the bearing remain intact despite these challenges.

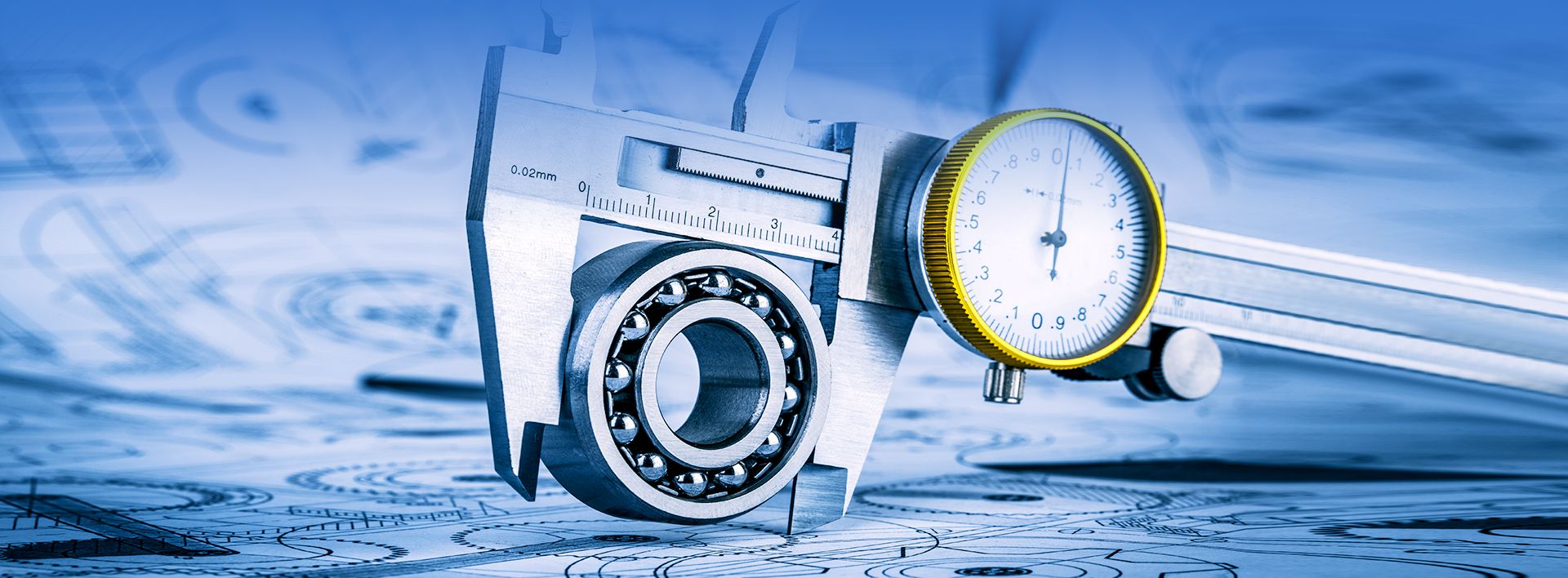

Quality Control and Superior Materials

1. Meticulous Material Selection:

Our bearings are manufactured using high-purity, premium specialty bearing steel, a material that undergoes rigorous metallurgical processing to ensure outstanding fatigue resistance. By controlling non-metallic inclusions within the steel, we significantly extend the bearing’s Fatigue Life, thereby guaranteeing long-term operational reliability.

2. Stringent Quality Processes:

From raw material sourcing to final product rollout, we implement a multi-stage, rigorous Quality Control process. Every product batch must pass numerous tests, including load capacity tests, sealing effectiveness tests, and durability simulations, ensuring that each hub unit meets or exceeds the industry’s highest performance standards.

Comprehensive Design Solutions

We offer a complete product range to meet various vehicle design and maintenance needs:

- Generation 1 (Gen 1) Design: The classic separate bearing and hub design, which offers greater flexibility and ease of maintenance in certain applications.

- Generation 3 (Gen 3) Design: The highly integrated Hub Unit, which combines the bearing, flange, and often sensors into a single assembly. This design boasts higher rigidity, a more streamlined installation process, and facilitates Maintenance-Free operation.

All designs, regardless of generation, are equipped with optimized sealing systems. These multi-lip, low-friction seals serve as the final line of defense against moisture and contaminants entering the raceway area, providing Maximum Protection Against Ingress for the bearing.

Related products

Specification Standards

| Key Feature | Standard Requirement | NSB Offering |

|---|---|---|

| Bearing Type | Tapered Roller or Double Row Angular Contact Ball | Tapered Roller for heavy duty, Angular Contact for compact systems. |

| Sealing System | Multi-lip contact seals | Highly robust seals with internal grease retention features. |

| Material Grade | High Carbon Chromium Steel (GCR15/SAE 52100) | Advanced heat treatment for superior wear resistance. |

| Integrated Sensors | Optional ABS/magnetic encoder seals | Available for seamless integration with vehicle safety systems. |

| Corrosion Resistance | High | Specifically designed to repel moisture and road salt. |

Applications

-

Passenger Cars: Front and rear axles of sedans, hatchbacks, and SUVs.

-

Commercial Vehicles: Light and medium-duty trucks, vans, and delivery vehicles.

-

Trailers: Utility trailers, boat trailers, and RV axles (often requiring Tapered Roller sets).

-

Off-Road Vehicles: ATV/UTV systems where contamination is extreme.

Key Advantages

-

Enhanced Sealing Integrity: Proprietary multi-stage seal designs prevent water and dirt from compromising bearing life, a major cause of failure.

-

Superior Load Carrying Capacity: Engineered geometries and precise tolerances manage high cornering forces and road impacts efficiently.

-

Reduced Maintenance: Integrated Generation 3 units are pre-set, pre-greased, and ready-to-install, requiring zero maintenance after fitting.

-

Integrated ABS Functionality: Available with high-resolution magnetic encoder rings for reliable speed sensing and anti-lock braking.

Ningbo Sanya Bearing Co., Ltd. is a professional China Automotive Wheel Bearings Manufacturers and Custom Automotive Wheel Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.