Polymer Cage Automotive Bearings

-- Steady & Reliable Manufacturer --

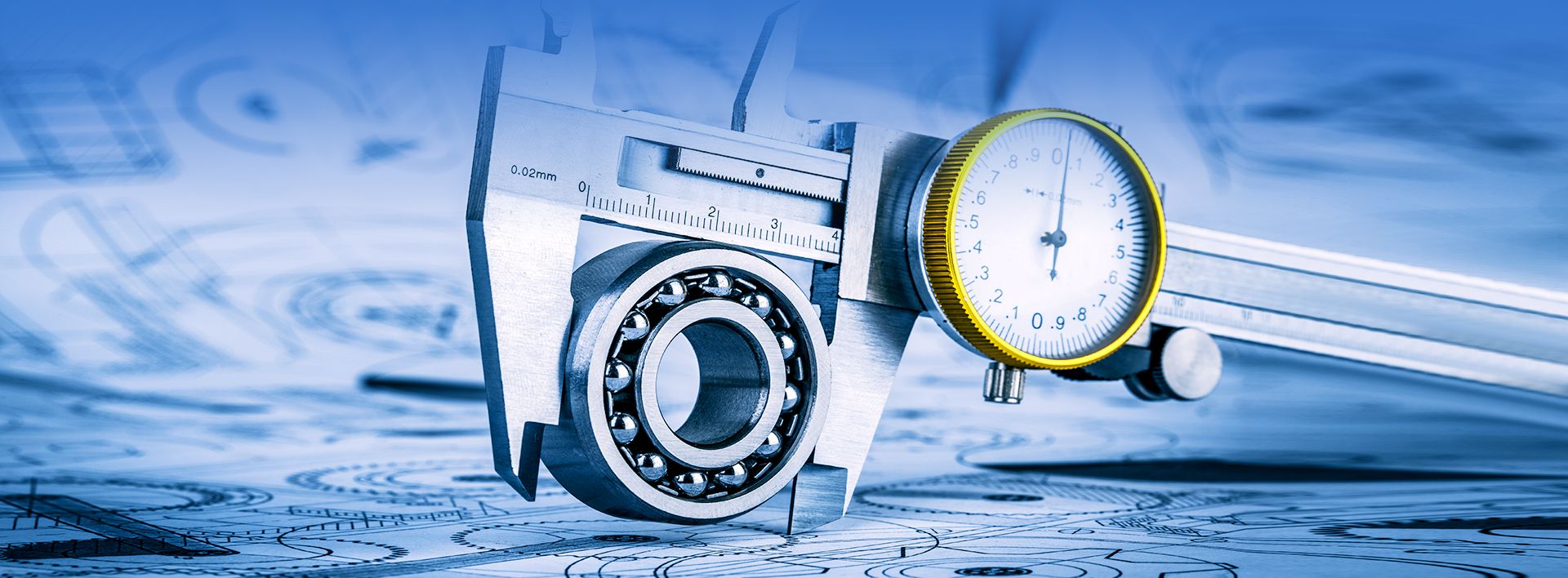

Introduction to Polymer Cage Technology for Automotive Systems

In the modern automotive sector, the push for NVH (Noise, Vibration, and Harshness) reduction and lighter vehicle components is relentless. Our Polymer Cage Automotive Bearings offer a crucial advantage by utilizing high-strength, glass-fiber reinforced Polyamide (PA66) cages. This design drastically reduces the bearing’s rotating mass, minimizes internal friction, and dampens operational noise compared to traditional stamped steel cages. They are meticulously crafted for non-drive-train auxiliary systems and electric vehicle (EV) components where high speed and low noise are performance mandates.

Related products

Technical Parameters of Polymer Cages

| Feature | Technical Requirement | NSB Advantage/Design |

|---|---|---|

| Bearing Type | High-Precision Deep Groove (DGBB) | Focused on 6000 and 6200 series for wide compatibility in motors and pulleys. |

| Cage Material | Glass-Fiber Reinforced Polyamide | Injection molded PA66-GF25 or similar composite offering excellent wear and chemical resistance. |

| Speed Rating | High Limiting Speed | Polymer's lighter weight allows for higher dynamic speed limits and lower centrifugal forces. |

| Thermal Limit | Operational Temperature Range | Guaranteed stability up to 120∘C (248∘F), suitable for most engine bay and chassis environments. |

| Surface Finish | Optimized Raceway Finishes | Super-finished races paired with the smooth polymer cage reduce friction and extend lubricant life. |

Common Automotive Applications

-

Vehicle Electrics: High-speed bearings for alternators, starter motors, and integrated starter generators (ISGs).

-

Climate Control: HVAC blower motors, idler pulleys, and compressors requiring exceptionally quiet operation.

-

Chassis Systems: Tensioner pulleys, small transmission components, and specific water pump assemblies.

-

Electric Vehicles (EVs): Auxiliary motors, cooling pumps, and cabin fan assemblies where noise is highly noticeable.

Superior Features and Customer Value

- Significantly Reduced Noise Profile:

The natural damping characteristics of polyamide reduce the transmission of structural vibration and noise, crucial for EV and premium vehicle acoustic targets.

- Excellent Chemical Resistance:

Resistant to most common automotive fluids, including oils, fuels, and coolants, ensuring cage integrity throughout the component’s lifecycle.

- Lower Frictional Torque:

The lighter cage mass and polymer's self-lubricating properties contribute to lower running temperatures and improved energy efficiency.

- Reduced Weight:

Contributing to the overall lightweighting strategy of modern vehicles, helping to improve performance and fuel economy/range.

Ningbo Sanya Bearing Co., Ltd. is a professional China Polymer Cage Automotive Bearings Manufacturers and Custom Polymer Cage Automotive Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.