Printing Machine Bearings

-- Steady & Reliable Manufacturer --

Brief Description

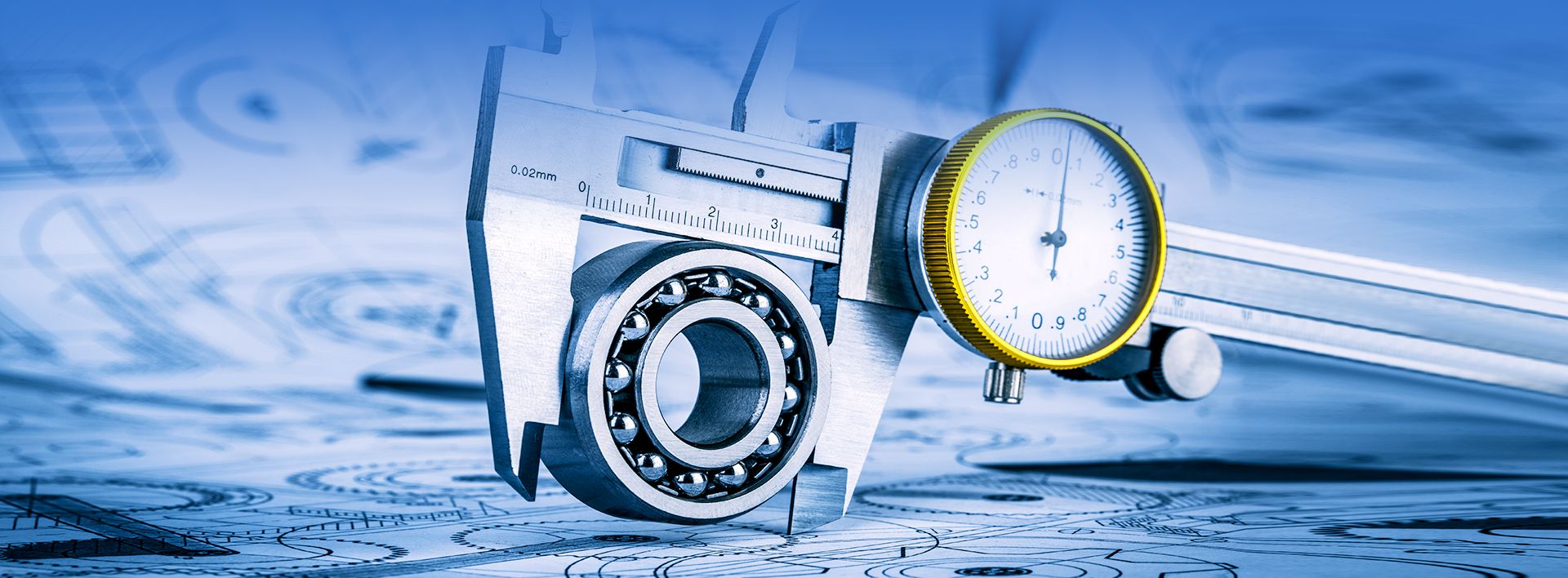

Ultra-high precision (P4/P2) bearings designed for printing cylinders and rollers, ensuring absolute minimum runout and low vibration for consistent, flawless high-speed image transfer.

Introduction

The quality of modern printing, especially offset and gravure, depends entirely on the rotational accuracy of the cylinders. This requires bearings of the highest precision class, often P4 (ABEC 7) or better, to maintain the extremely tight gap (the "kiss") between rollers. Our printing machine bearings are manufactured under strict conditions to ensure minimal radial and axial runout. Furthermore, they feature specialized sealing and shielding to protect against ink mist, paper dust, and cleaning chemicals, guaranteeing the extended operational life required by high-volume commercial printing.

Related products

Specification Standards

| Key Feature | Precision Class | NSB Offering |

|---|---|---|

| Precision Focus | P4 (ABEC 7) or P2 (ABEC 9) | Critical for zero runout and print accuracy. |

| Vibration Grade | V4 (Ultra-Low) | Ensures smooth rotation and prevents banding/ghosting. |

| Design Type | Single/Double Row Angular Contact, Thin Section | Supports high axial load from cylinder forces. |

| Protection | Shielded (ZZ) or Specialized Seals | Resistant to ink, solvents, and paper particles. |

| Cage Material | Phenolic Resin or High-Speed Polyamide | Optimized for high-speed operation and reduced friction. |

Applications

-

Offset Printing Presses: Cylinder and blanket roller support.

-

Gravure & Flexographic Printing: High-speed impression and metering rollers.

-

Digital Press Systems: Precision rollers for paper transport and image transfer.

-

Coating and Laminating Machines: High-accuracy finishing rollers.

Key Advantages

-

Flawless Print Quality: P4/P2 precision eliminates roller vibration and runout, preventing common printing defects like streaks and misalignment.

-

High Uptime at Speed: Components are optimized for continuous high-speed web or sheet-fed operation.

-

Chemical Resistance: Materials and sealing systems withstand exposure to printing inks and press cleaning solvents.

-

Reduced Heat Generation: High-precision elements and specialized cages minimize friction, reducing the need for complex cooling systems.

Ningbo Sanya Bearing Co., Ltd. is a professional China Printing Machine Bearings Manufacturers and Custom Printing Machine Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.