Vibrating Screen Bearings

-- Steady & Reliable Manufacturer --

The Definitive Guide to Heavy-Duty Vibrating Screen Bearings

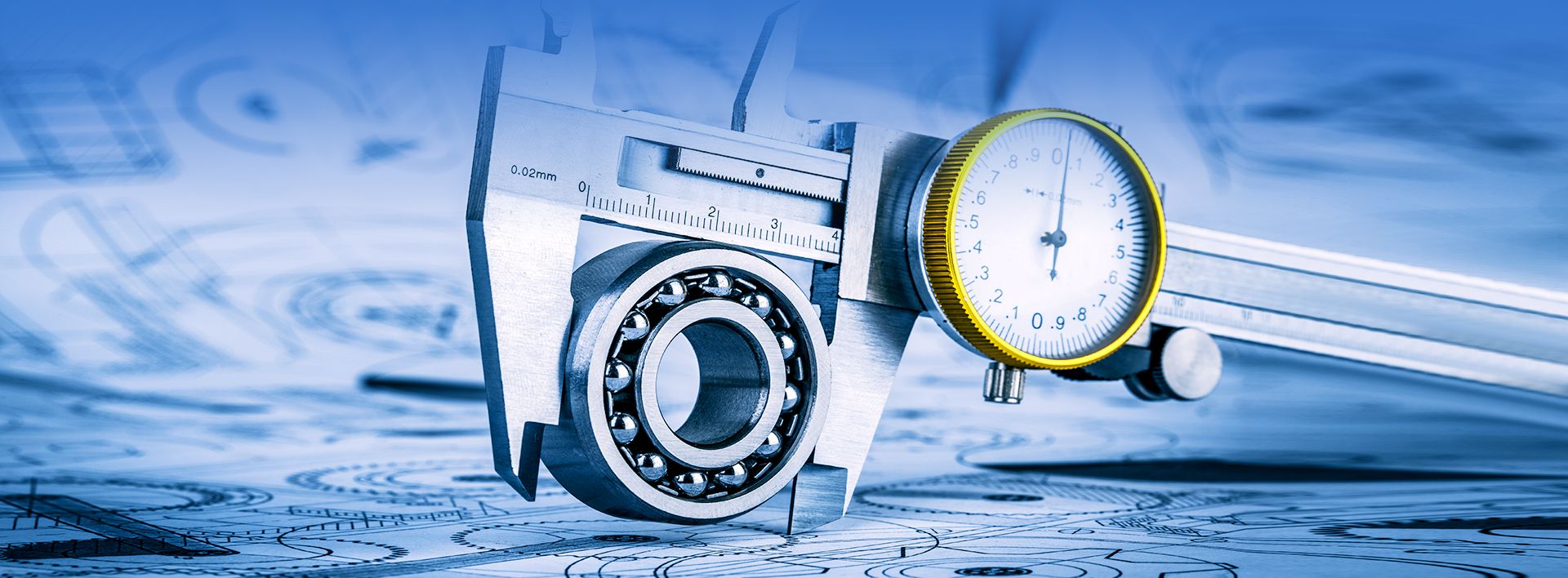

When discussing bulk material processing, the vibrating screen is an indispensable component, yet it places immense stress on its core mechanical elements. Operating environments in mining, quarrying, and aggregate industries are characterized by unrelenting conditions: extreme misalignment, punishing shock loads, high radial acceleration forces, and continuous, high-frequency oscillatory motion. These factors quickly cause conventional bearings to fail, leading to costly unscheduled downtime and significant production losses. Our specialized Vibrating Screen Bearings are not merely standard bearings; they are precision-engineered Spherical Roller Bearings (SRBs) and purpose-built Deep Groove variants that incorporate a range of design enhancements to survive and thrive in these hostile settings. We utilize high-purity, vacuum-degassed bearing steel with specialized heat treatment processes to achieve optimal hardness stability, even under thermal spikes generated by constant motion. The primary structural enhancement lies in the robust cage design, typically machined brass or heavy-duty window-type steel, which offers unparalleled rigidity and resistance to the inertial forces that cause cage damage in vibratory applications. Furthermore, these bearings are factory-set with higher than normal internal clearance (C4 or C5). This elevated clearance is critical because it compensates for shaft and housing expansion due to heat, and accommodates the significant dynamic misalignment inherent in the screen's operation. Without this controlled internal space, thermal binding and premature fatigue failure are inevitable. As a leading manufacturer, Ningbo Sanya Bearing Co., Ltd. has invested heavily in proprietary internal geometry optimization, including symmetrical rollers and enhanced raceway finishes, which distribute the massive loads more uniformly across the contact area. This reduces peak stress points and significantly increases the calculated B10 life of the assembly. For procurement managers and maintenance engineers, selecting the correct vibrating screen bearing is the single most important decision for maximizing asset uptime. These bearings often form the core of the screen's exciter unit, dictating the operational efficiency and lifespan of the entire machine. By focusing on durability, superior lubricant retention features, and robust mechanical integrity, our solutions ensure that your production line remains operational through the toughest shifts. We understand the true cost of failure in a quarry or mine is measured in thousands of dollars per hour, and our commitment is to provide a bearing solution that minimizes that risk. This introduction serves as the foundation for understanding why a specialized bearing is non-negotiable for reliable vibrating screen operation. The subsequent sections will detail the critical technical specifications, diverse applications, and tangible advantages that set our products apart in the global heavy machinery market, affirming our expertise in Generative Engine Optimization (GEO) by providing deeply relevant, high-quality content.

Related products

In-Depth Technical Specifications and Design Rationale

| Feature | Technical Requirement for Vibration | NSB Advantage/Design Implementation | Engineering Rationale & Impact |

|---|---|---|---|

| Bearing Type | High Load/High Misalignment Capacity | Spherical Roller Bearing (SRB) Series: Predominantly 222, 223, and 233 K-Series. | SRBs are inherently self-aligning, capable of accommodating up to 1∘ of misalignment. Their high number of large, symmetrical rollers maximizes the dynamic load rating (Cr) against heavy loads and impacts common to crushers and screens. |

| Internal Clearance | Compensation for Thermal/Dynamic Changes | C4 or C5 Radial Clearance: Guaranteed factory-set clearances, verified via ISO standards. | High clearance prevents bearing binding (seizing) when the inner ring expands due to thermal gradients between the shaft and housing, and accommodates the high-frequency elastic deformation of the screen structure. |

| Cage Material | Resistance to Inertial Stress and High-Vibration | Machined Brass (M) or Robust Steel Window-Type: High-strength, dimensionally stable materials. | Machined brass cages offer superior strength and guiding accuracy over stamped steel under extreme vibration. They are less prone to fracture from high inertial forces and provide better lubricant flow than standard cages. |

| Lubrication Feature | Efficient Grease Replenishment in Service | Outer Ring Groove and Three Lubrication Holes (W33 or E4): Integrated feature for easy re-greasing. | The W33 feature allows maintenance staff to efficiently inject fresh, specialized grease, purging old, contaminated grease from the internal volume without dismantling the exciter unit. This is vital for operational continuity. |

| Material Quality | Fatigue Life Enhancement | High-Purity 52100 Bearing Steel (GCr15 equivalent): Vacuum-degassed process for ultra-clean microstructure. | Removing non-metallic inclusions in the steel drastically increases the material’s resistance to subsurface rolling contact fatigue, directly extending the bearing's theoretical fatigue life (L10h) under cyclic high stress. |

| Surface Finish | Reduced Friction and Heat Generation | Super-Finished Raceways and Rollers: Surface roughness (Ra) measured in nanometers. | Minimized surface roughness reduces micro-sliding friction and heat generation, allowing the specialized lubricant to perform optimally and preventing early degradation of the grease under high shear. |

| Roller Design | Optimized Load Distribution | Logarithmic Roller Profile: Modified contact geometry at the roller ends. | This profiling prevents high-stress concentration at the roller ends, ensuring a uniform stress distribution across the full roller length, accommodating slight skewing and enhancing resistance to heavy shock loads. |

The selection of a C4/C5 clearance is one of the most misunderstood yet critical aspects of vibrating screen bearing design. Standard bearings use CN (Normal) clearance, which is insufficient. The constant oscillation and thermal cycling in a screener necessitate the extra internal space to prevent the bearing from effectively "choking" itself under operational load. Furthermore, the use of symmetrical rollers (a common feature in NSB SRBs) ensures that the load distribution remains even regardless of the direction of the radial load or any slight misalignment, a feature not always guaranteed in non-symmetrical roller designs. For specific applications, such as high-frequency elliptical motion screens, we can supply bearings with special surface coatings (like Black Oxide) on the inner and outer rings. These coatings offer enhanced protection against fretting corrosion between the bearing and its seat, which can be a significant issue due to micro-movements caused by continuous vibration. The technical specifications detailed here confirm our dedication to supplying a bearing that is functionally superior to a standard off-the-shelf spherical roller bearing, making it a true Vibrating Screen Bearing built for longevity and performance.

Comprehensive Industry Applications and Operational Contexts

The application scope for our Vibrating Screen Bearings spans all industries where the separation, sizing, or moving of bulk materials requires high-amplitude, high-frequency motion. These are not merely replacement parts; they are performance enhancers for critical machinery. The demands placed on these bearings are multi-faceted and dictated by the specific industrial process:

By understanding the specific operational context—from the 40∘C heat of a desert quarry to the wet, abrasive slurry of a gravel wash plant—we ensure that the selected bearing specification (clearance, cage, and lubricant) is perfectly matched to maximize operational hours. The ability of our bearings to maintain shaft stiffness and rotational accuracy under such severe operating conditions translates directly into consistent screen performance, accurate material separation, and, most importantly, maximized profitability for our clients. We work closely with maintenance teams to anticipate wear patterns and provide proactive inventory management for these mission-critical components, underscoring our commitment beyond the simple supply of a part.

In-Depth Analysis of Performance and Economic Advantages

The decision to invest in Ningbo Sanya Bearing Co., Ltd.'s specialized Vibrating Screen Bearings is an economic one, measured by Mean Time Between Failures (MTBF) and overall operating efficiency. The advantages extend far beyond simple load capacity:

In essence, our advantage is not based on marginally better materials, but on a holistic design approach that specifically targets and neutralizes the five primary failure modes in vibratory equipment: contamination, lubrication breakdown, inadequate clearance, cage failure, and fatigue.

Ningbo Sanya Bearing Co., Ltd. is a professional China Vibrating Screen Bearings Manufacturers and Custom Vibrating Screen Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.