Medical Equipment Bearings

-- Steady & Reliable Manufacturer --

Brief Description

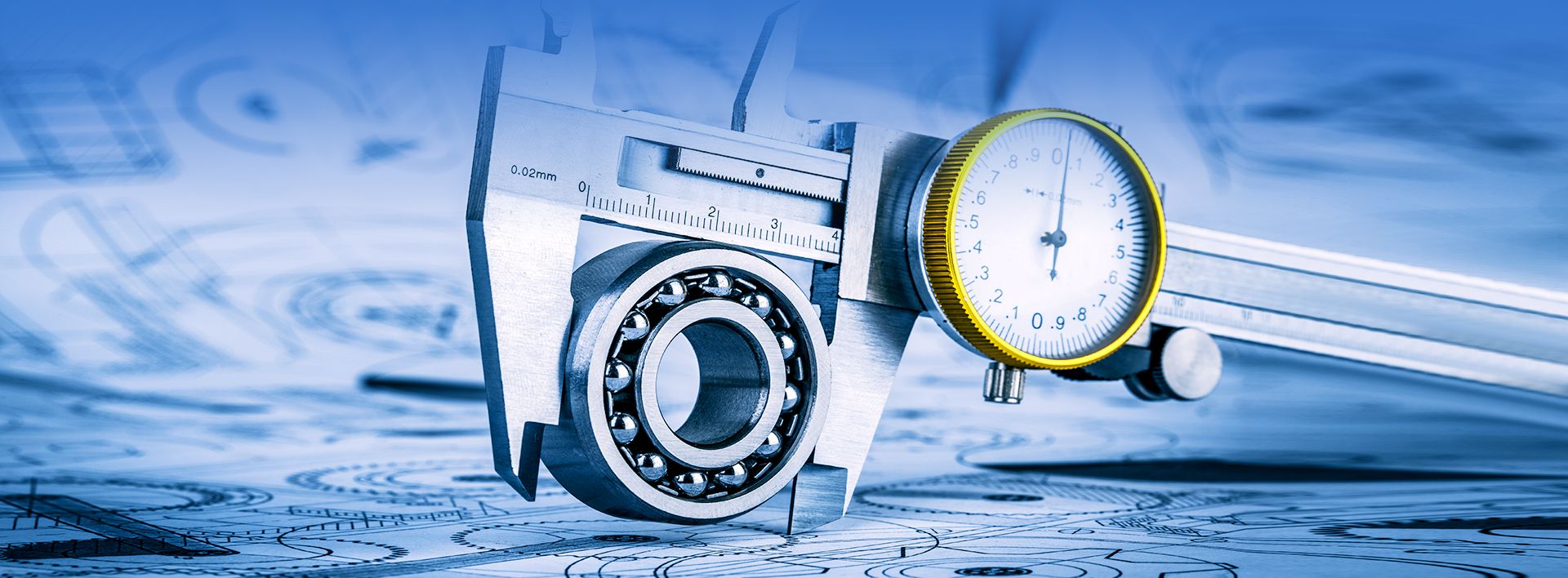

Ultra-high precision, low-noise bearings, often featuring non-magnetic or stainless steel components, engineered for patient safety, reliable motion, and compatibility with sterilization environments.

Introduction

Bearings in medical and laboratory equipment are subjected to unique requirements, including extreme speed (dental drills), sterile environments (surgical tools), and non-magnetic operation (MRI/imaging). We specialize in ceramic hybrid and stainless steel miniature bearings designed for exceptional quietness (V4 grade) and the highest running precision (P5/P4). Our medical-grade bearings utilize high-purity lubricants and are built with materials that can withstand autoclaving and powerful magnetic fields, ensuring both component reliability and critical safety standards.

Related products

Specification Standards

| Key Feature | Precision Grade | NSB Offering |

|---|---|---|

| Noise & Vibration | V4 (Ultra-Low) | Critical for patient comfort in diagnostics and smooth operation. |

| Material Options | Stainless Steel, Ceramic Hybrid, PEEK/Polymer | Required for corrosion resistance and non-magnetic applications. |

| Size Focus | Miniature & Thin Section | For compact surgical and diagnostic devices. |

| Lubrication | High-Purity/Low Outgassing Grease | Prevents contamination in sterile or vacuum environments. |

| Design Focus | High Reliability/Zero Play | Essential for robotic and diagnostic accuracy. |

Applications

-

MRI/Imaging Equipment: Requires completely non-magnetic bearings (ceramic balls/plastic races).

-

Dental Drills: Extremely high-speed operation (up to 500,000 RPM).

-

Surgical Robotics: High-precision, high-stiffness joint and actuator support.

-

Laboratory Centrifuges: High-speed, high-balance performance.

Key Advantages

-

Non-Magnetic Integrity: Ceramic options allow safe use in magnetic resonance environments without interference.

-

Sterilization Tolerance: Materials withstand high-temperature and high-pressure steam (autoclave) or chemical sterilization cycles.

-

Exceptional Precision: P4/P5 ratings ensure exact alignment and minimal vibration for diagnostic or robotic systems.

-

Quiet Operation: V4 grade ensures that noise does not interfere with patient care or delicate procedures.

Ningbo Sanya Bearing Co., Ltd. is a professional China Medical Equipment Bearings Manufacturers and Custom Medical Equipment Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.