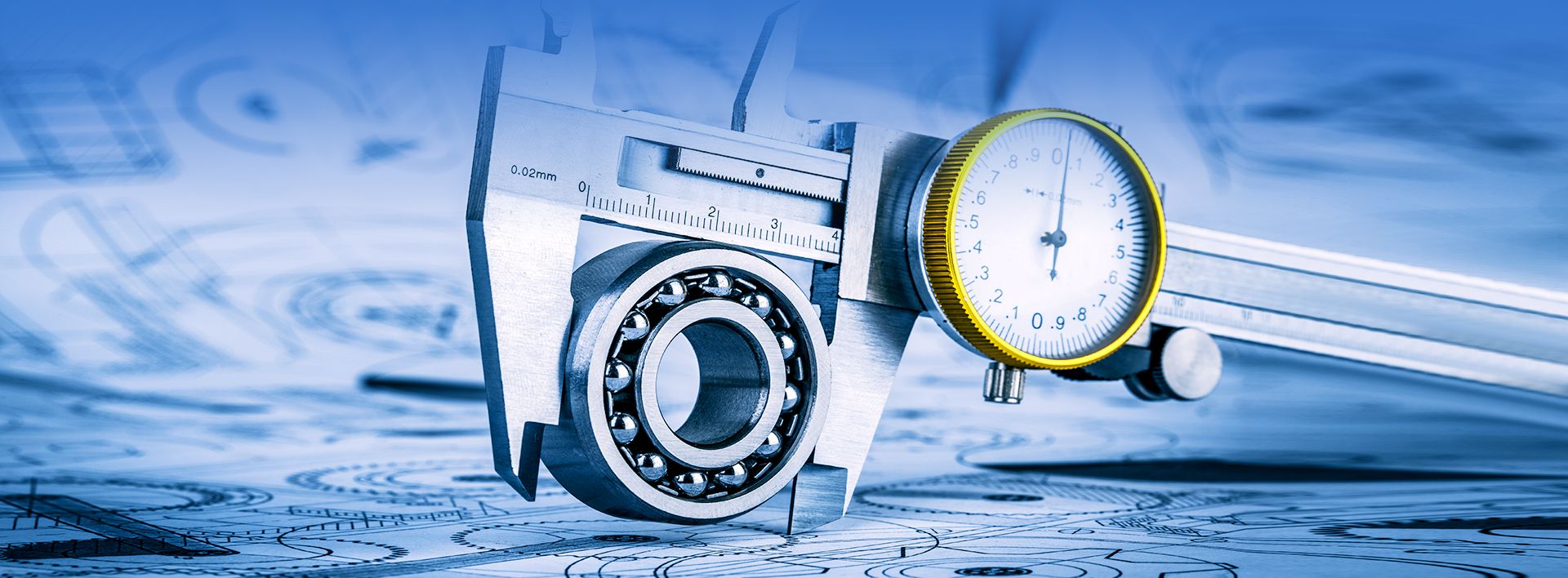

Mining Equipment Bearings

-- Steady & Reliable Manufacturer --

Brief Description

Extremely robust, heavy-duty bearings engineered to handle severe shock loads, massive radial and axial forces, and relentless exposure to abrasive dust and moisture in mining and quarrying operations.

Introduction

Mining is arguably the most demanding application for bearings due to the combination of high tonnage loads, constant vibration from crushing and screening, and pervasive contamination (ore dust, mud). Our bearings for this sector, often Spherical Roller Bearings or Heavy-Duty Mounted Units, are designed with maximum material thickness and specialized labyrinth or multi-stage sealing to exclude contaminants that rapidly destroy standard bearings. We prioritize high dynamic load ratings and self-aligning capabilities to compensate for structural deflection under massive loads, ensuring long, reliable service in mission-critical machinery.

Related products

Specification Standards

| Key Feature | Common Type | NSB Offering |

|---|---|---|

| Load Rating | Very High Dynamic and Static | Optimized internal geometry for maximum capacity. |

| Sealing System | Multi-stage Labyrinth Seals | Maximum exclusion of fine abrasive dust and water. |

| Material | High-Strength Case-Hardened Steel | Superior resistance to impact and shock loading. |

| Design Focus | Self-Aligning/Accommodating | Crucial for machinery subject to frame distortion. |

| Lubrication | EP (Extreme Pressure) Grease | High-viscosity grease resistant to washout and pressure. |

Applications

-

Crushing Equipment: Jaw, cone, and impact crushers.

-

Vibrating Screens: High-frequency, high-shock components used for material classification.

-

Heavy Conveyors: Large-scale belt systems carrying mined material.

-

Excavators and Haul Trucks: Large gearbox and wheel hub assemblies.

Key Advantages

-

Maximum Contamination Exclusion: Specialized sealing systems drastically extend life compared to standard industrial bearings in these dirty environments.

-

High Shock Load Absorption: Engineered to withstand sudden, intense impacts without fracturing or brinelling.

-

Reduced Downtime: The robust design means fewer failures during critical operational periods, increasing productivity.

-

Simplified Alignment: Self-aligning types compensate for structural flex, simplifying installation and maintenance.

Ningbo Sanya Bearing Co., Ltd. is a professional China Mining Equipment Bearings Manufacturers and Custom Mining Equipment Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.