Low-Friction Tapered Roller Kits

-- Steady & Reliable Manufacturer --

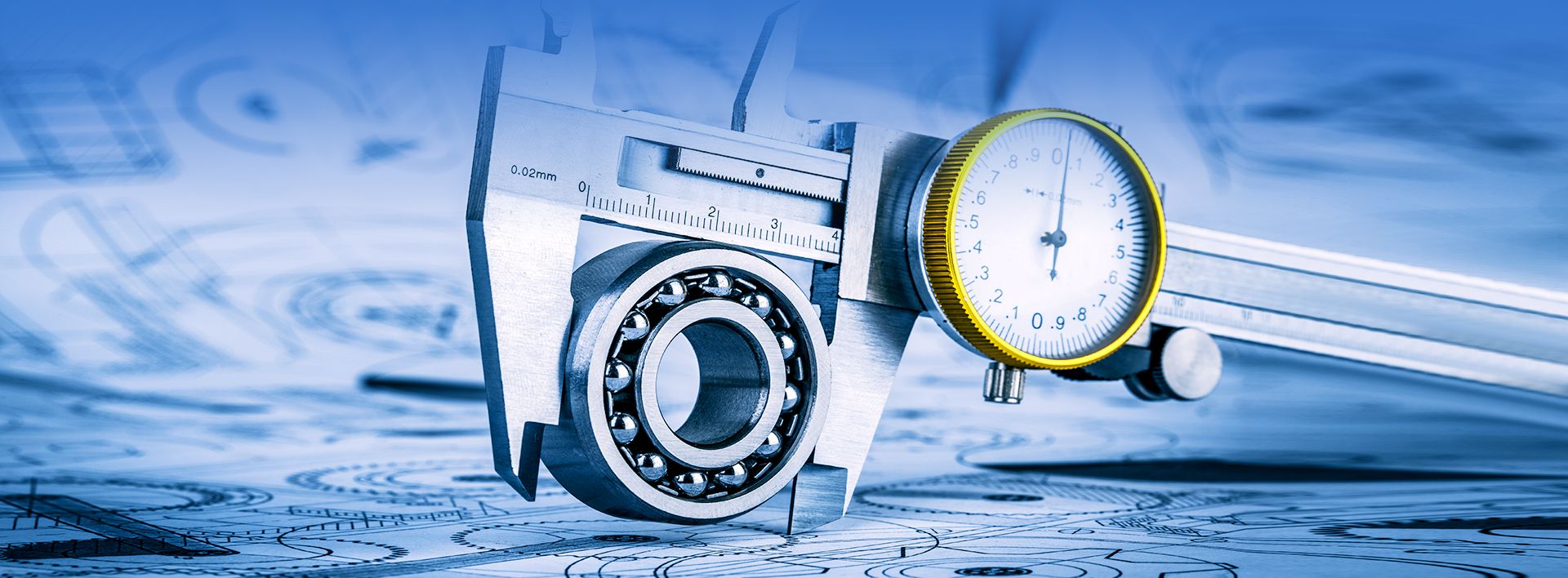

Introduction to Energy-Efficient Taper Roller Bearing Sets

In heavy-duty applications like truck axles, industrial gear drives, and mill stands, minimizing energy waste through friction is a critical performance and sustainability goal. Our Low-Friction Tapered Roller Kits are precision-matched cone and cup sets engineered with optimized roller end geometry and superior surface finishes. These design improvements significantly reduce the coefficient of friction, leading to lower operating temperatures, reduced lubricant degradation, and tangible energy savings compared to conventional tapered bearings. They are supplied as ready-to-mount kits, ensuring correct matching.

Related products

Technical Parameters of Friction Reduction

| Feature | Technical Requirement | NSB Advantage/Design |

|---|---|---|

| Bearing Type | Single-Row Taper Roller Bearings (TRBs) | Matched cone and cup sets for differential or wheel applications. |

| Friction Reduction | Optimized Roller End Design | Proprietary profiling of the roller ends and flange contact surfaces minimizes sliding friction. |

| Material | High-Cleanliness Hardened Steel | Vacuum-degassed steel ensures fewer inclusions, increasing fatigue life. |

| Setting Tolerance | Zero-Deflection Setting Capability | Kits are matched to allow for precise setting of running clearance or preload to maximize stiffness. |

| Lubrication Method | Oil or Heavy-Duty Grease Compatible | Internal design promotes efficient lubricant flow and heat dissipation. |

Energy-Sensitive Applications

-

Commercial Vehicles: Wheel end assemblies and differential pinions in long-haul trucks and trailers.

-

Heavy Industrial Gearboxes: Input and output shafts in high-torque, continuously running gear drives.

-

Wind Turbines: Pitch and yaw mechanisms where precise, low-torque operation is required.

-

Rolling Mills and Presses: Axial and radial support for high-load process machinery.

Operational and Sustainability Advantages

- Substantial Energy Savings:

Reduced friction translates directly into lower power consumption for the driving element, improving operational efficiency.

- Lower Operating Temperature:

Reduced heat generation extends the life of the lubricant, slows the degradation of seals, and improves overall reliability.

- Extended Service Life:

Superior cleanliness of the steel and optimized internal geometry increases the theoretical L10 and L50 bearing fatigue life.

- High Load Capacity:

Maintains the high radial and single-direction axial load capacity inherent to the tapered roller geometry.

Ningbo Sanya Bearing Co., Ltd. is a professional China Low-Friction Tapered Roller Kits Manufacturers and Custom Low-Friction Tapered Roller Kits Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.