Ceramic Hybrid Bearings

-- Steady & Reliable Manufacturer --

Brief Description

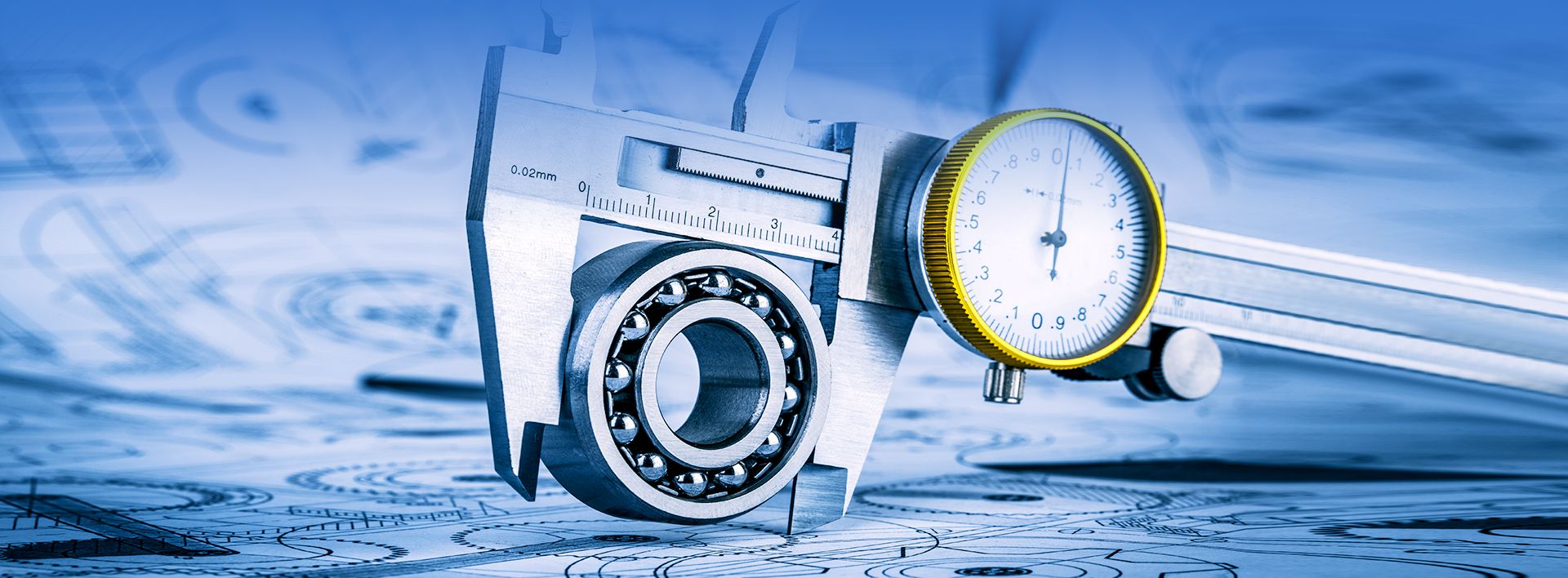

Bearings featuring silicon nitride (Si3N4) ceramic rolling elements and chrome steel rings, designed for extreme speed, electrical isolation, and high stiffness in critical, high-performance machinery.

Introduction

Ceramic Hybrid Bearings combine the best qualities of steel and advanced ceramics. The ceramic balls (typically silicon nitride, Si3N4) are lighter, harder, and non-conductive, while the steel races provide the necessary structural strength. This combination enables the bearing to run at dramatically higher speeds (higher DN values) and cooler temperatures than all-steel counterparts, while also providing complete electrical insulation, preventing damage from shaft currents in electric motors. They are the ideal solution for machine tool spindles, electric vehicle motors, and applications requiring low density and high acceleration.

Related products

Specification Standards

| Key Feature | Rolling Element Material | NSB Offering |

|---|---|---|

| Speed Capability | Extreme (Higher DN Value) | Lighter balls lead to less centrifugal force and heat. |

| Electrical Property | Insulating | Blocks damaging circulating currents in motors/generators. |

| Precision Class | P5 or P4 (ABEC 5/7) | Required for the intended high-speed applications. |

| Density | Low | Reduces overall component mass and friction. |

| Lubrication | Oil or Minimal Grease | Optimized to take advantage of the ceramic's low friction. |

Applications

-

Machine Tool Spindles: High-speed CNC routing and milling.

-

Electric Motors & Generators: Traction motors (EVs) and high-power generators (shaft current protection).

-

Turbochargers & Vacuum Pumps: High-temperature, ultra-high-speed rotation.

-

High-Performance Cycling: Hubs and bottom brackets (for reduced weight and friction).

Key Advantages

-

Electrical Discharge Protection: Ceramic balls act as insulators, protecting motors from WEC (White Etching Cracks) and electrical erosion damage.

-

High Rotational Speed: Achieves significantly higher DN values than all-steel bearings due to the lower mass of the balls.

-

Reduced Friction and Heat: Smoother ceramic surface and low friction torque ensure cooler, more energy-efficient running.

-

Extended Service Life: Ceramic balls are harder, resist contamination better, and are less susceptible to false brinelling.

Ningbo Sanya Bearing Co., Ltd. is a professional China Ceramic Hybrid Bearings Manufacturers and Custom Ceramic Hybrid Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.