Pump Bearings

-- Steady & Reliable Manufacturer --

Brief Description

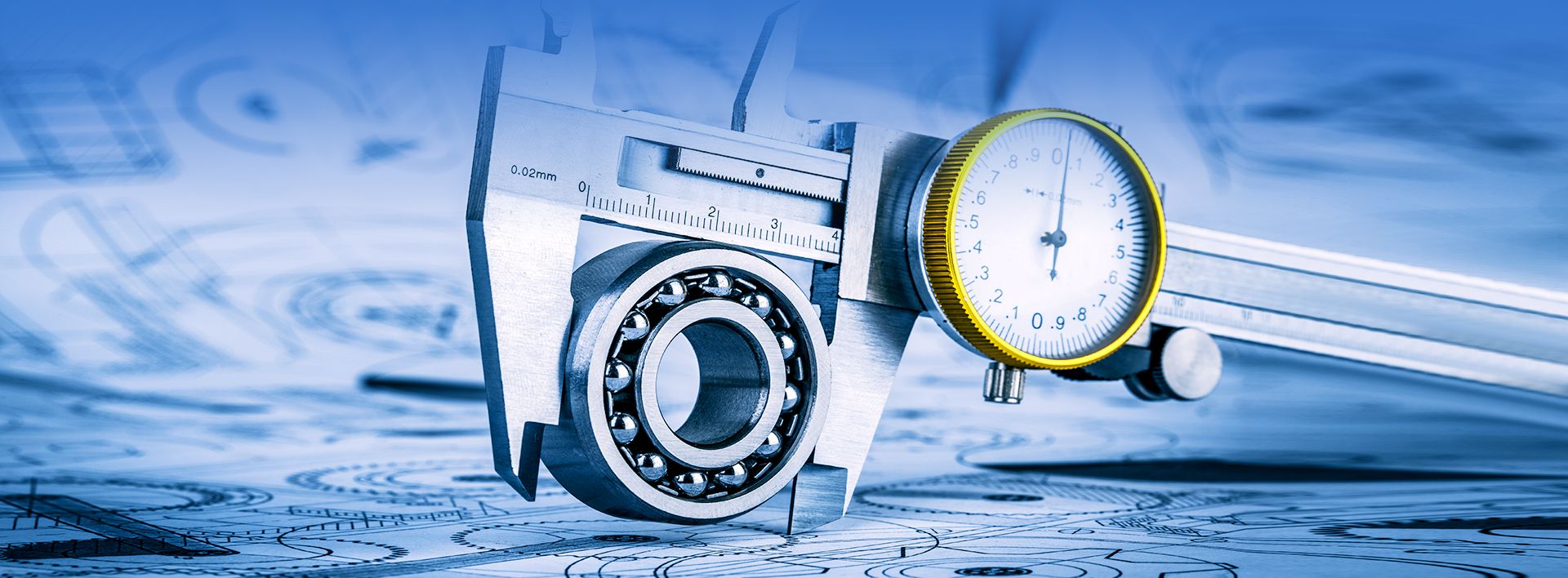

Precision bearings, often Angular Contact Ball Bearings (ACBB), optimized to manage both the high radial loads of the impeller and the critical thrust loads generated by fluid movement in industrial pumps.

Introduction

Bearings in fluid pumps (centrifugal, vertical, and chemical) face unique challenges, primarily handling the high axial (thrust) load caused by the fluid impeller and maintaining rotational stability near high moisture/corrosion sources. We supply high-precision, typically P5 or P6 grade, ACBBs often supplied in duplex (paired) arrangements to precisely handle the thrust forces in two directions. Our focus on superior sealing and corrosion-resistant materials ensures maximum mean time between failures (MTBF), which is critical for continuous process industries like oil & gas, water treatment, and chemical processing.

Related products

Specification Standards

| Key Feature | Common Type | NSB Offering |

|---|---|---|

| Type Focus | Angular Contact Ball Bearings (ACBB) | Optimized for combined radial and axial loads. |

| Arrangement | Duplex Pair (e.g., Back-to-Back or Face-to-Face) | Precise load sharing and rigidity for thrust control. |

| Precision Class | P6 to P5 (ABEC 3 to 5) | High precision to prevent vibration and ensure reliable seal operation. |

| Housing Interface | Often mounted in separate bearing units (cartridges) | Ensures ease of assembly and maintenance. |

| Corrosion Resistance | High | Optional stainless steel or specialized coatings for chemical pumps. |

Applications

-

Water Treatment: Centrifugal pumps and booster pumps.

-

Oil & Gas: High-pressure process pumps and submersible pumps.

-

Chemical Industry: Pumps handling aggressive or corrosive fluids (requires stainless steel or ceramic).

-

HVAC Systems: Circulation pumps and cooling tower systems.

Key Advantages

-

Superior Thrust Control: Precision-matched duplex sets handle high thrust loads more effectively than standard bearings, preventing shaft walk.

-

Extended Seal Life: High bearing precision ensures stable shaft running, maximizing the effectiveness of external shaft seals (mechanical seals).

-

Corrosion Resilience: We offer material options suitable for high-humidity or direct fluid contact environments.

-

Low Vibration: High precision translates directly into quieter, more stable pump operation and longer seal life.

Ningbo Sanya Bearing Co., Ltd. is a professional China Pump Bearings Manufacturers and Custom Pump Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.