High-Temperature Deep Groove Bearings

-- Steady & Reliable Manufacturer --

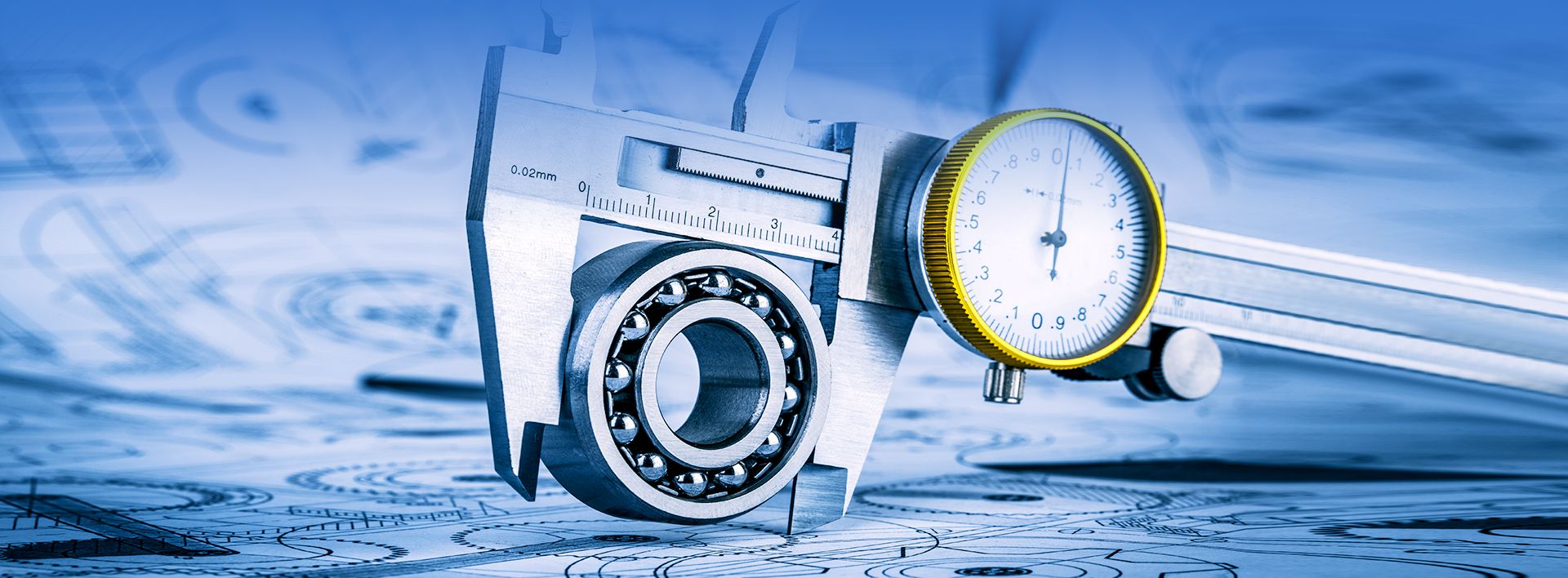

Introduction to High-Heat Endurance Ball Bearings

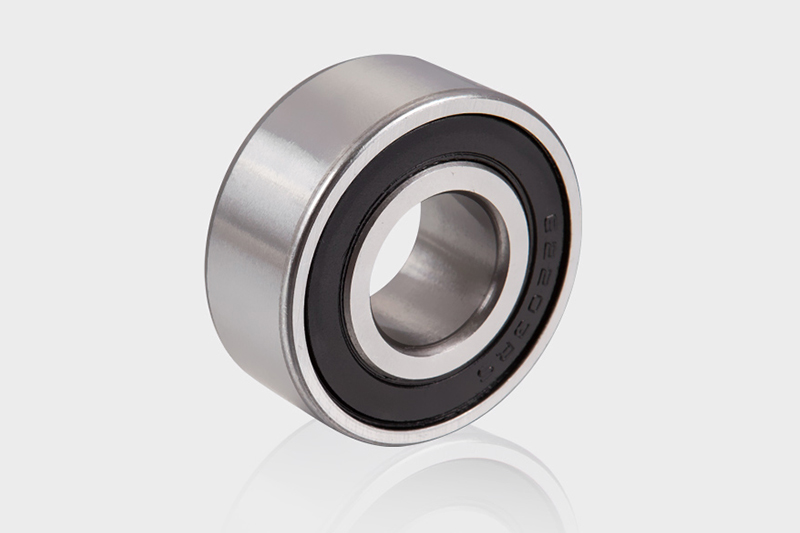

In industrial processes like baking, drying, and metallurgy, standard bearings quickly fail due to grease breakdown and material softening. Our High-Temperature Deep Groove Bearings are specifically engineered to operate reliably in environments up to 350∘C (662∘F). They feature specialized high-carbon chromium steel, optimized radial internal clearance (C4 or C5), and solid lubricants like graphite or advanced high-temperature grease. This design eliminates issues like cage creep and lubricant evaporation, ensuring smooth, extended operation in ovens, kilns, and smelters.

Related products

Technical Parameters for Extreme Heat

| Feature | Technical Requirement | NSB Advantage/Design |

|---|---|---|

| Operating Temperature | Continuous use up to 350∘C | Materials and heat treatment are stabilized to maintain hardness at elevated temperatures. |

| Internal Clearance | High Radial Clearance (C4/C5) | Mandatory C4 or C5 clearance to compensate for extreme thermal expansion of the shaft and housing. |

| Lubrication | Solid Graphite or High-Temperature Fluorinated Grease | Specialized, low-evaporation solid or synthetic lubricants that do not carbonize at high heat. |

| Cage Material | Stamped Steel or No Cage (Full Complement) | Avoids polymer or brass, which would soften; full complement allows maximum load but lower speed. |

| Radial and Axial Load | Reduced Dynamic Load Rating | Load capacity is derated due to reduced material hardness at high temperature, requiring careful selection. |

Common High-Temperature Applications

-

Industrial Ovens and Dryers: Bearings for kiln cars, furnace conveyor rollers, and paint curing ovens.

-

Food Processing: Commercial baking equipment, dough mixers, and high-heat sterilization chambers.

-

Metallurgy: Cooling beds and rolling mill equipment where heat dissipation is limited.

-

Exhaust and Boiler Fans: Motor and fan support exposed to extreme exhaust heat.

Advantages in Thermal Environments

- Reliable Operation at Extreme Heat:

Withstands temperatures that would destroy conventional bearings and lubricants, maintaining structural integrity and hardness.

- Eliminates Lubrication Issues:

Solid lubrication provides lifetime operation without re-greasing, preventing costly manual maintenance cycles in inaccessible high-heat zones.

- Minimized Thermal Stress:

Specific C4/C5 clearance prevents internal binding and premature failure caused by differential thermal expansion.

- Corrosion Resistance:

Treated steel and specialized coatings resist high-temperature oxidation and scaling.

Ningbo Sanya Bearing Co., Ltd. is a professional China High-Temperature Deep Groove Bearings Manufacturers and Custom High-Temperature Deep Groove Bearings Suppliers.And it established in 1994 stands right at the prime location of the Yangtze River Delta. Specialized in the production of high-quality deep groove ball bearings and insert bearings. It has emerged as a modern company integrating product development, design, manufacturing, sales and service. It can produce bearings with an inner diameter of 3mm to 100mm and customize various non-standard Custom Series 6000 Two Contact Seals Deep Groove Ball Bearing with highly-automated equipment, stable quality, and complete testing methods ensuring the quality of its products. With the vigorous development of the foreign trade department, our business in bearing production and sales in 2018 far exceeded 20 million US dollars, and the products were sold in more than 50 countries and regions.