Series 1600 Chrome Steel Deep Groove Ball Bearing

Product Overview The Series 1600 Deep Groove Ball ...

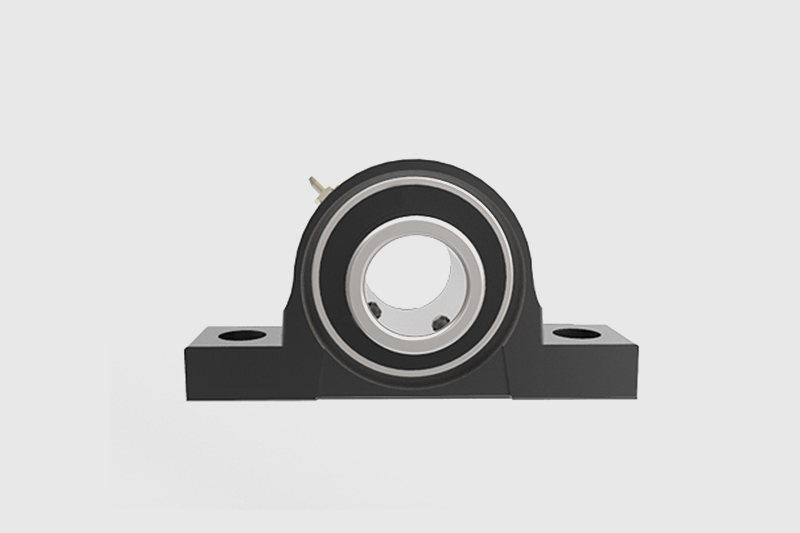

Pillow block units (also known as support bearings) are common foundational components in industrial machinery, typically used to support rotating shafts and effectively reduce friction. They play a vital role in improving equipment efficiency, extending service life, and reducing failures.

1. Introduction to Pillow Block Units

Pillow block units are assemblies consisting of a housing, bearing, and support base. They are typically used to support mechanical shafts and maintain their correct position. They are widely used in various industrial equipment, such as motors, conveyor systems, pumps, and fans.

Basic Function

The main function of a Pillow Block Unit is to support bearings, reduce radial movement of the shaft, and ensure good contact between the shaft and the bearing. By reducing friction, they effectively improve the stability and efficiency of mechanical operation.

Common Applications

Industrial Automation: Used to support mechanical components such as conveyor belts and robotic arms.

Manufacturing: Pillow Block Units provide shaft support and reduce wear in heavy equipment and production lines.

Agricultural Machinery: Pillow Block Units can be used to improve operational precision in equipment such as tractors and seed drills.

2. How Do Pillow Block Units Improve Equipment Efficiency?

How do Pillow Block Units work to improve equipment efficiency? They provide powerful support for equipment in the following ways. Reduce Friction and Energy Loss

Pillow Block Units significantly reduce energy loss by reducing friction between shafts and bearings. Lower friction means less energy is required to operate the equipment, resulting in more efficient machine operation. This benefit is particularly pronounced in high-speed equipment.

Provide Greater Stability and Precision

Pillow Block Units help maintain precise shaft alignment and stable operation. By reducing vibration and radial loads, they ensure high-precision operation, thus avoiding mechanical failure and reduced efficiency caused by shaft misalignment.

Adapt to Various Environments and Extend Equipment Life

High-quality Pillow Block Units are made of wear-resistant materials and can withstand a variety of harsh environments (such as high temperature, high humidity, and chemically corrosive environments). This not only reduces maintenance requirements but also extends the overall life of the equipment, reducing downtime caused by bearing wear.

3. How to Choose the Right Pillow Block Unit?

Choosing the right Pillow Block Unit is the first step to ensuring efficient equipment operation. When selecting, you should consider the following key factors:

Load Requirements

Load is one of the most important factors when selecting a Pillow Block Unit. Different bearing seat designs can handle different load capacities. If your equipment operates with heavy loads, it's crucial to choose a Pillow Block Unit that can handle greater loads.

Speed Requirements

For high-speed equipment, choosing a Pillow Block Unit with a high speed capacity will help reduce friction and improve efficiency. Different types of bearing seats can accommodate different speeds, so choosing the right model depends on the specific requirements of your equipment.

Material Selection

The material of a Pillow Block Unit directly impacts its performance and service life. Common materials include:

Cast iron: Suitable for heavy loads and moderate speeds.

Aluminum alloy: Suitable for equipment requiring lightweight construction.

Stainless steel: Suitable for use in high-humidity, chemically corrosive environments.

4. Installation Tips: Ensuring Optimal Performance

Proper installation is crucial to ensuring your Pillow Block Unit maximizes equipment efficiency. Here are some installation tips to help you avoid common mistakes and ensure optimal performance:

Ensure Shaft Alignment

During installation, ensure the shaft is perfectly aligned with the Pillow Block Unit's bearing seat. This reduces excess load and friction during operation, preventing unnecessary vibration and noise. Evenly Distribute the Load

When installing multiple Pillow Block Units, ensure that the load is evenly distributed across all bearing seats. This helps reduce excessive wear on individual bearings and improves overall equipment stability and durability.

Securely Secure the Bearing Seats

Failure to do so can lead to loosening and failure during operation, compromising equipment efficiency. Ensure proper fastener use to prevent any loosening.

5. Maintenance Tips: Extend Life and Maintain Efficient Operation

To keep your Pillow Block Units operating efficiently and effectively over time, regular maintenance and care are essential. Here are some maintenance tips:

Regularly Check Lubrication

Check the lubrication of your Pillow Block Units regularly to ensure sufficient lubrication and cleanliness. Insufficient lubrication can cause excessive friction and accelerated wear, reducing equipment efficiency.

Cleaning the Bearings and Housing

Clean your Pillow Block Units regularly, especially in dusty or humid environments. Dust and dirt can interfere with proper operation and reduce efficiency.

Sealing Protection

Many Pillow Block Units are equipped with seals to effectively prevent dirt from entering the bearings. If the seal is damaged, it should be replaced promptly to ensure long bearing life and efficient operation.

6. Case Study: Pillow Block Units in Practical Application for Improving Efficiency

Through real-world examples, we can more intuitively understand the value of Pillow Block Units. For example, on an automated production line, high-quality Pillow Block Units were used to support the rotating shafts of the conveyor system. Through optimized installation and regular maintenance, the production line's failure rate was reduced by 25%, and equipment operating efficiency increased by 15%. Similar success stories are common across various industries, and Pillow Block Units have become a vital tool for improving production efficiency.