Series 1600 Chrome Steel Deep Groove Ball Bearing

Product Overview The Series 1600 Deep Groove Ball ...

Content

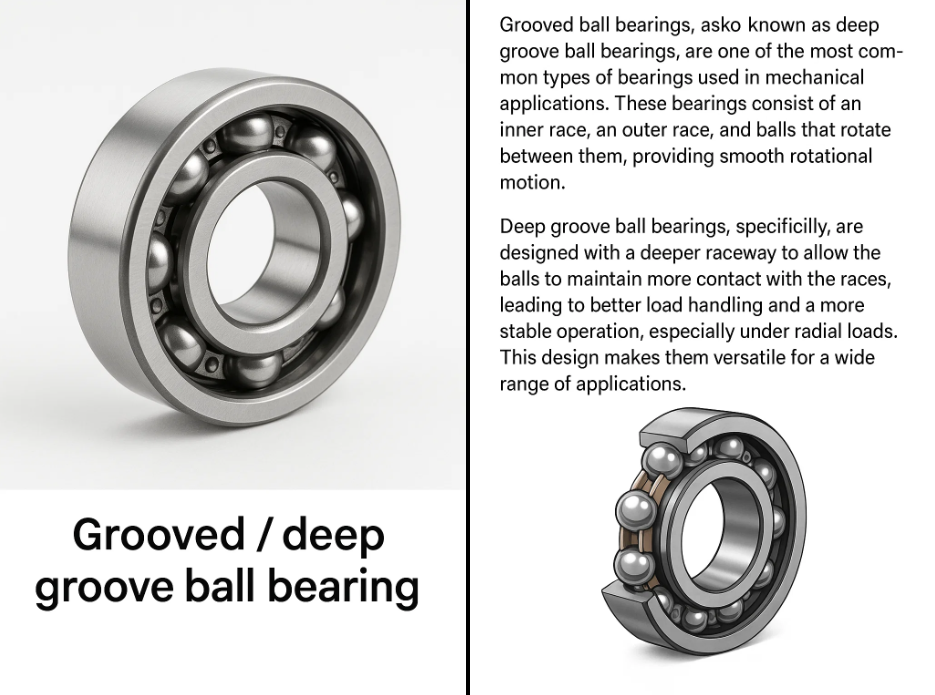

Grooved ball bearings, also known as deep groove ball bearings, are one of the most common types of bearings used in mechanical applications. These bearings consist of an inner race, an outer race, and balls that rotate between them, providing smooth rotational motion. The “groove” refers to the deeper raceway in the design that helps accommodate higher loads and offer smoother motion.

Deep groove ball bearings, specifically, are designed with a deeper raceway to allow the balls to maintain more contact with the races, leading to better load handling and a more stable operation, especially under radial loads. This design makes them versatile for a wide range of applications.

Understanding the differences between grooved (deep groove) ball bearings and other types, such as cylindrical roller bearings, is critical for selecting the right bearing for specific applications. Choosing the right bearing type can influence performance, longevity, and efficiency in machinery, from high-speed operations in electric motors to heavy-duty uses in machinery. By recognizing the specific advantages and limitations of each type, engineers can make more informed decisions that contribute to the reliability and cost-effectiveness of their designs.

Deep groove ball bearings are one of the simplest and most versatile bearing designs. Their basic structure consists of three main components:

The raceway (groove) in deep groove ball bearings is designed to be deeper than standard ball bearings. This deeper groove allows for greater contact between the balls and the races, which increases load capacity and improves stability. The groove is typically circular, which helps reduce friction during rotation.

Deep groove ball bearings are typically shielded or sealed to protect the balls from dirt, moisture, and other contaminants, ensuring long-lasting performance. They come in various sizes, with the most common being the single-row variety, though two- and three-row designs are also available.

The load capacity of deep groove ball bearings is primarily radial but also includes some ability to handle axial (thrust) loads.

Radial Load Capacity: This is the ability of the bearing to support loads that are perpendicular to the shaft. Deep groove ball bearings have a good radial load capacity for their size and are able to handle moderate radial loads with ease. The radial load capacity is usually higher when the bearing is designed with larger ball sizes.

Axial Load Capacity: Unlike angular contact bearings, deep groove ball bearings can also handle axial loads (loads parallel to the shaft), but the capacity is relatively lower. The axial load capacity is limited because the balls are not in direct contact with the races at a specific angle as in angular contact designs.

| Load Type | Deep Groove Ball Bearings |

|---|---|

| Radial Load | High (depending on size) |

| Axial Load | Moderate (less than angular contact bearings) |

Deep groove ball bearings are widely used in a variety of applications due to their versatility. Some common applications include:

Deep groove ball bearings offer several key advantages:

Despite their advantages, deep groove ball bearings have limitations:

Cylindrical roller bearings are designed to carry radial loads and are constructed with cylindrical rollers placed between two raceways (the inner and outer rings). Unlike ball bearings, which use spherical balls, cylindrical roller bearings use rollers that are in direct line contact with the raceways, increasing the bearing’s load-carrying capacity.

The main components of a cylindrical roller bearing are:

Cylindrical roller bearings typically come in both single-row and multi-row designs, with the single-row design being the most common. The rollers are aligned in a single row, but multi-row configurations can provide additional load-bearing capacity, which is useful in heavy-duty applications.

Cylindrical roller bearings are designed primarily to support radial loads, and their load-carrying capacity is generally higher than that of ball bearings due to the larger contact area between the rollers and the raceways. The key characteristics of load capacity in cylindrical roller bearings are:

Radial Load Capacity: Cylindrical roller bearings have a higher radial load capacity compared to deep groove ball bearings. This makes them suitable for applications with high radial forces, such as heavy machinery, industrial gearboxes, and motor shafts.

Axial Load Capacity: Cylindrical roller bearings have a lower axial load capacity compared to angular contact ball bearings and deep groove ball bearings. While they can handle some axial load, they are better suited for applications where axial forces are not predominant.

| Load Type | Cylindrical Roller Bearings | Deep Groove Ball Bearings |

|---|---|---|

| Radial Load | Very High | Moderate |

| Axial Load | Low to Moderate | Moderate |

Cylindrical roller bearings are commonly used in applications where high radial load capacity is needed, such as:

Cylindrical roller bearings offer several key advantages:

Despite their strong load-carrying capacity, cylindrical roller bearings have limitations:

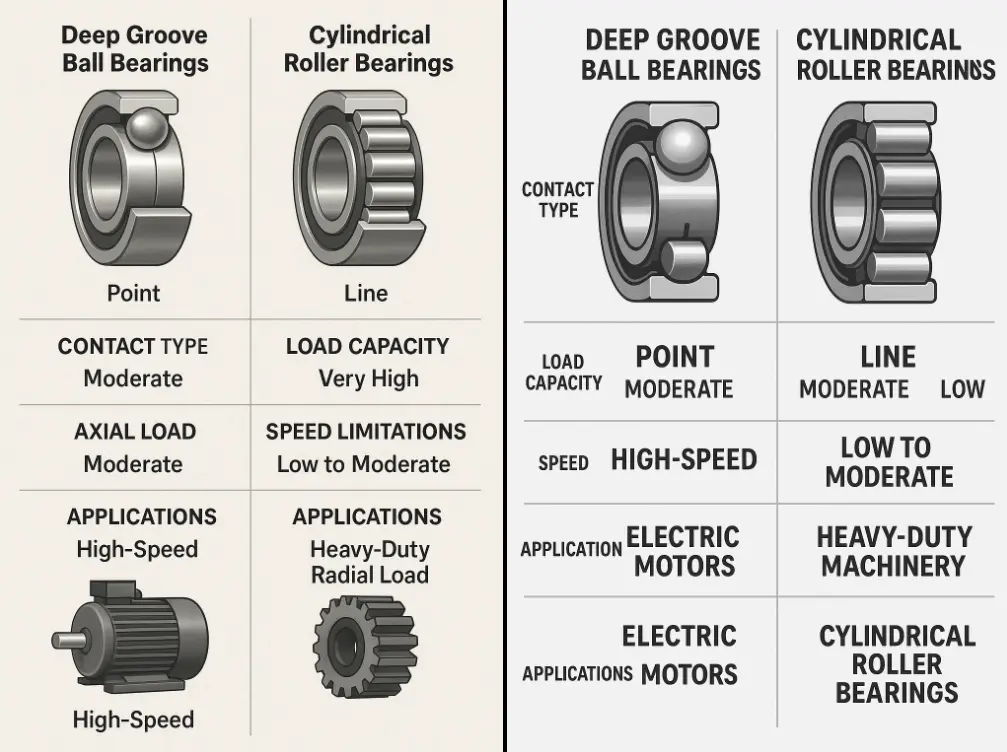

One of the primary differences between deep groove ball bearings and cylindrical roller bearings is the contact type between the rolling elements and the raceways.

Deep Groove Ball Bearings: The contact between the balls and the raceways is point contact. This means that only a small point of the ball touches the raceway at any given time. This results in lower friction but also means that the load is distributed over a smaller area, which can limit the bearing’s load capacity, especially for heavier radial loads.

Cylindrical Roller Bearings: In contrast, cylindrical roller bearings use line contact between the cylindrical rollers and the raceways. This larger contact area enables the bearing to handle much higher radial loads than ball bearings, making them ideal for heavy-duty applications.

The load capacity of the two bearings differs significantly due to their structural designs.

Radial Load Capacity:

Axial Load Capacity:

| Load Type | Deep Groove Ball Bearings | Cylindrical Roller Bearings |

|---|---|---|

| Radial Load | Moderate | Very High |

| Axial Load | Moderate | Low to Moderate |

Speed capabilities are another key differentiator between the two bearing types:

Deep Groove Ball Bearings: These bearings are designed for high-speed applications. Due to the point contact between the balls and the raceways, there is less friction, allowing for smoother rotation and faster speeds. This makes them suitable for applications like electric motors, where high speeds are common.

Cylindrical Roller Bearings: While cylindrical roller bearings can handle heavy loads, they are generally not suited for high-speed applications. The line contact between the rollers and the raceways results in more friction compared to ball bearings, which increases heat generation and limits their speed capabilities. These bearings are typically used in low to moderate speed applications, where heavy radial loads are more prevalent.

The primary applications of deep groove ball bearings and cylindrical roller bearings also differ due to their respective load capacities and speed characteristics:

Deep Groove Ball Bearings:

Cylindrical Roller Bearings:

| Application Type | Deep Groove Ball Bearings | Cylindrical Roller Bearings |

|---|---|---|

| High-Speed Applications | Excellent | Limited |

| Heavy-Duty Radial Load | Moderate | Excellent |

| Axial Load Handling | Moderate | Low |

| General Industrial Machinery | Excellent | Good |

Deep groove ball bearings are a versatile and widely used bearing type, well-suited for a variety of applications. Here are scenarios where deep groove ball bearings would be the preferred choice:

High-Speed Applications: If the application requires high-speed rotation, deep groove ball bearings are an ideal choice due to their low friction and ability to operate at higher speeds with less heat generation. Common examples include:

Light to Moderate Radial and Axial Loads: In applications where both radial and moderate axial loads are present, deep groove ball bearings excel because they can support both types of loads simultaneously. Some examples include:

Low Maintenance Applications: When low maintenance is a key requirement, deep groove ball bearings are a great choice due to their sealed or shielded designs that help protect them from dirt, dust, and moisture. This makes them ideal for:

Compact Applications: If space is constrained, deep groove ball bearings are a good option because of their relatively small and compact design. Applications might include:

Cylindrical roller bearings are preferred in situations where heavy radial loads are common, but speed is not a primary concern. Here are the typical scenarios where cylindrical roller bearings excel:

Heavy-Duty Radial Load Applications: When the application requires a bearing that can withstand high radial loads, cylindrical roller bearings are the best choice due to their higher load capacity. Common examples include:

Low to Moderate Speed Applications: Cylindrical roller bearings are suited for applications with lower to moderate speeds, where their high radial load capacity can be fully utilized without the limitations of high-speed operation. Examples include:

High Shock Load Situations: Cylindrical roller bearings are well-suited for applications where bearings are subjected to shock loads or high-impact forces. Their robust design allows them to absorb such forces better than deep groove ball bearings. Some examples include:

Heavy Machinery in Harsh Environments: When operating conditions involve high levels of contamination, dirt, or dust, cylindrical roller bearings (especially sealed types) are used in heavy machinery and industrial settings. These include:

| Scenario | Deep Groove Ball Bearings | Cylindrical Roller Bearings |

|---|---|---|

| High-Speed Applications | Excellent | Limited |

| Heavy Radial Load Applications | Moderate | Excellent |

| Low to Moderate Axial Loads | Excellent | Limited |

| Low Maintenance & Compact Space | Excellent | Limited |

| Shock Load and Harsh Conditions | Limited | Excellent |

To wrap up, let’s quickly recap the key differences between deep groove ball bearings and cylindrical roller bearings:

Design & Contact Type:

Load Capacity:

Speed and Maintenance:

Selecting the correct bearing type is crucial for ensuring optimal performance, longevity, and reliability of the machinery or equipment. Using the wrong bearing in a given application can lead to several issues, including premature wear, failure, and inefficient operation, which can ultimately lead to costly repairs and downtime.

For instance, using deep groove ball bearings in heavy-duty industrial machinery where high radial loads are prevalent would result in bearing overload, excessive heat, and premature failure. On the other hand, using cylindrical roller bearings in high-speed applications would limit performance, as these bearings are not designed to handle the speeds at which ball bearings can operate.

To avoid these issues, it’s essential to: